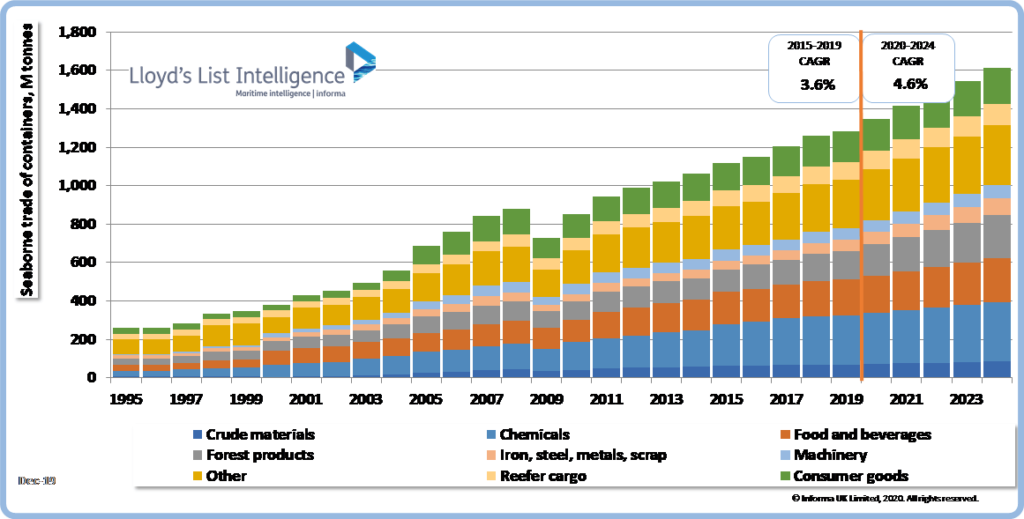

Container shipping is big business. There are about 20 million shipping containers in circulation right now, with seaborne containerized cargo amounting to around 1.85 billion tons in 2020.

Shipping containers are durable, safe, and secure. Thanks to their high degree of standardization, they can be stacked on various modes of transport, and tracked across the world with special codes. It’s not surprising that the global container shipping market is expected to surpass $12 billion in 2027.

However, it’s not all plain sailing. The price of containers, as well as the general cost of shipping, is currently high due to the disruption caused to global supply chains by the pandemic and a shortage of containers. If you’re planning to ship your goods by this method, it’s important that you mitigate these costs as much as possible.

Source: lloydslist.maritimeintelligence.informa.com

How Can Brightpearl Reduce Your Shipping Container Costs?

The rise in container rates means your business needs to think carefully about how it can reduce costs—both for shipping and across your other operations. Using smart software can help you do that, and Brightpearl’s retail operations system gives you a variety of tools to increase efficiency.

For example, the new Inventory Planner application helps you order products based on volume or weight so that you can ensure shipping containers are filled efficiently or that the shipment meets a certain weight limit. Once you’ve logged the CBM (cubic meters) or weight for each item, it will display in your purchase orders, enabling you to estimate how many cubic meters of container space is required.

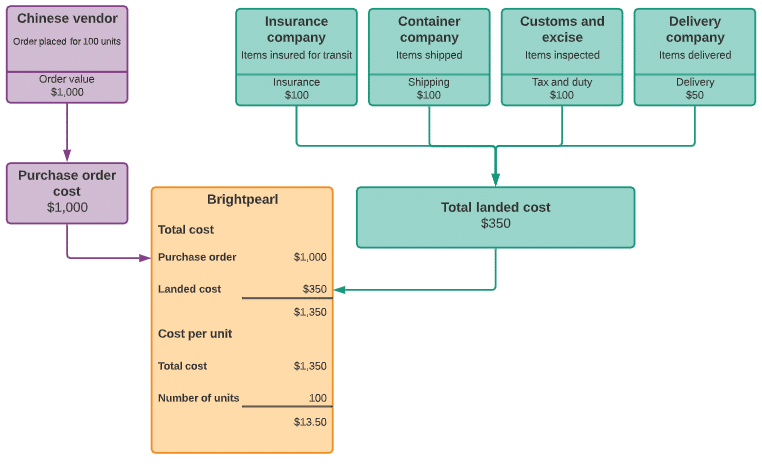

Brightpearl also has a tool to help you figure out your landed costs, which include hiring a shipping container, the cost of transporting it by land, air, or sea, insuring the goods during transit, and any duties and taxes payable for international import and export. It’s easy to allocate landed costs to your stock before inventory is shipped—just make sure that “Activate landed costs” is set to “Yes” in your Purchase Settings.

Knowing exactly how much stock you have, and forecasting how much you’re going to need in future, will help you to calculate accurate container shipping costs and set your budget accordingly. Brightpearl gives you full visibility of your inventory levels so that you don’t end up placing bulk orders for goods you don’t really need, or paying for unused space in a half-full container.

Brightpearl integrates with all major shipping companies and 3PL firms, so you can exchange information, track the progress of your shipments at all times, and optimize container routing to reduce costs. If you have negotiated good deals with several carriers (perhaps one for national deliveries and another for international shipping), you can manage them all in one place with Brightpearl.

What are Shipping Containers?

A shipping container is a long box made of a durable material such as steel. It is typically used to transport goods over a long distance. You’re probably picturing a huge ship loaded with containers, but they’re not only used for ocean freight—you can also transport goods in containers via rail or road.

Container shipping, or containerization, has been around for a while. American trucking entrepreneur Malcom McLean is credited with revolutionizing the industry in the 1950s, when he launched commercial shipping company Sealand (now owned by Maersk) to speed up the movement of goods along the US east coast.

Before shipping containers became popular, goods for transportation were stored in a variety of crates and bags and had to be loaded onto ships individually. While containers helped to streamline the process, they weren’t standardized until the late 1960s when the International Organization for Standardization (ISO) established consistent dimensions.

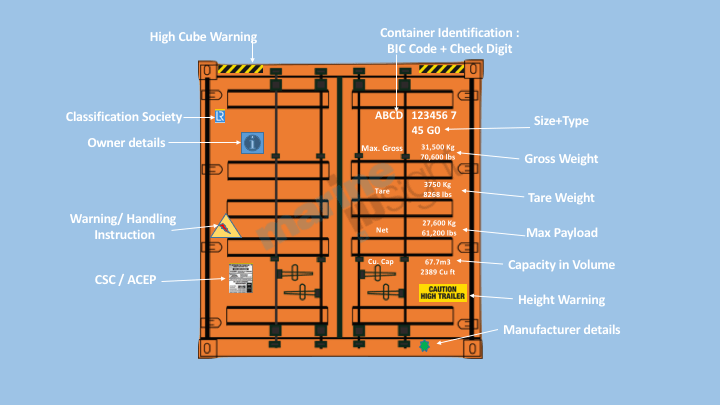

A global standard for size and capacity means that containers can easily be stacked together for transport or storage. The ISO also standardized the information displayed on each container so that any port in the world can recognize it. This includes an identification number and manufacturer information.

Types of Shipping Containers

ISO standards dictate that all shipping containers must be 8ft wide, 8.5ft tall, and a length of either 20ft or 40ft, as this is the most efficient size for worldwide shipping. However, there are different container shapes and sizes that allow more specialized cargo.

Containers are made from material that offers maximum protection to goods in transit. Most use either a special steel alloy called corten (waterproof and affordable), or an aluminum alloy, (lighter and corrosion-resistant, but more expensive). Less commonly, containers can be made from FRP (fiber reinforced plastic), fiberboard, or wood.

New Containers

Choosing brand new containers can be the most expensive option, but if you’re transporting high value or fragile goods, you’ll want to be confident that the container can protect them against the elements. And if you need a specialized container, such as the refrigerated or insulated variety, a new model will be in optimum working condition.

However, some companies find that it actually costs them less to buy a new container than it would to transport a used one back to its origin or another place where it could be refilled. As crazy as that may sound, there’s no point wasting money on bringing empty containers back to your depot.

Used Containers

The above means that there’s a thriving market for used containers, some of which many only have been used for a single journey. But even if they have been across the world several times over, shipping containers are designed to be extremely durable and weather-resistant—they can last as long as 25 years.

You may find that a used container has a few exterior scratches and dents or a bit of rust, but the interior will keep your items just as safe and secure as a brand-new container. There are plenty of container Leasing companies offering used containers, and you can sometimes find them on Craigslist or eBay.

Source: marineinsight.com

Refurbished Containers

These are also used containers, but they’ve been fixed up to look as good as new. Suppliers of refurbished or renovated containers can cover up shipping decals from other companies and replace them with your own logo, or just give them a plain paint job. They’ll also perform minor repairs if required, and remove any rust and corrosion to help the container last longer.

If you are going to use a refurbished or used container, it’s worth checking that it’s completely watertight and weather-proof. It’s best to get an authorized inspection to make sure the container meets the criteria set by the International Convention for Safe Containers (CSC). These inspections must be carried out periodically by the owner or operator of any container.

Dry Storage

This is the most common type of container for international shipping. It’s designed to transport dry goods, and protects the cargo by sealing it from outside moisture and weather. As well as the standard size, you can get “high cube” containers which are a foot taller at 9’6” tall, to allow more stacking room for larger goods. These are most common in 40 ft lengths.

There’s a tunnel type that opens at both ends to allow cargo to be loaded and unloaded faster, and containers where the sides open for loading by forklift, too. There’s also an open-top version for tall or bulky cargo, which can be loaded from above by crane before the roof is reattached.

Flat Rack

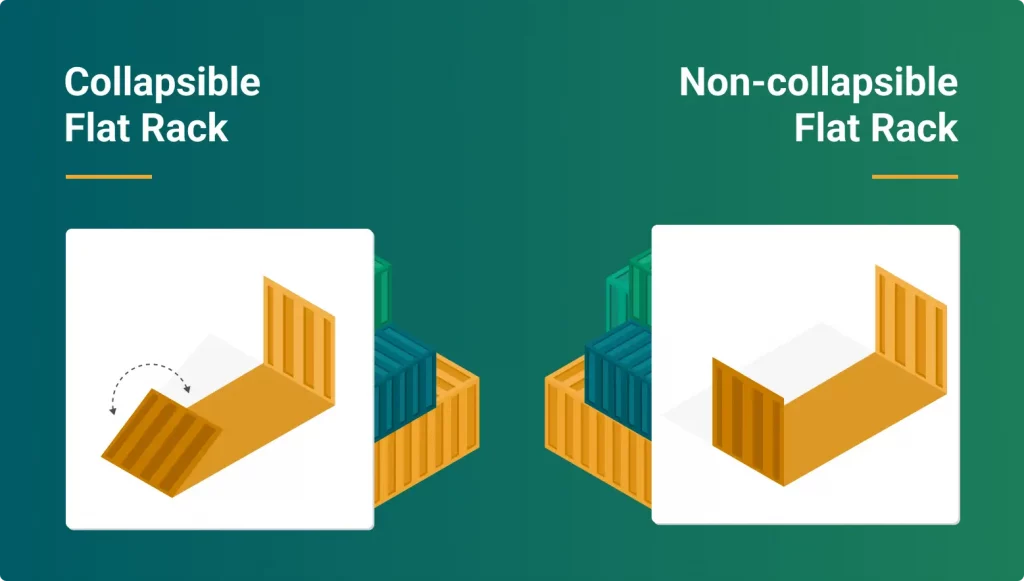

Flat rack containers typically have no side walls or roofs, although some of them do have collapsible sides. They are used to transport cargo that is oddly-shaped or very heavy and bulky (vehicles, boats, engines, machinery, timber) because it’s easy to load and unload from the top. The two end walls may also be removable or collapsible.

Flat racks come in both 40ft and 20ft container sizes, with standard widths and heights. Empty collapsible flat racks can be stacked together for more efficient carriage, with four of them taking up roughly the same space as one regular dry storage container.

Source: container-xchange.com

Refrigerated

In the shipping industry, refrigerated containers are nicknamed “reefers”. They are used for shipping food, medicines, or other perishable items such as fresh flowers. These containers enable consumers to enjoy fresh produce imported from around the world, when it’s out-of-season or not grown in their own region.

Refrigerated containers are either 20 or 40ft long, and use an air-cooled or water-cooled system or a generator to ensure a consistent temperature. The internal walls are constructed using material with low thermal conductivity to minimize variation in the temperature range, which is typically between 65˚C and 40˚C.

Insulated

Insulated containers basically do the opposite job to refrigerated ones. They are used for transporting perishable goods that need to be kept at a higher temperature than outside, such as some fresh produce and pharmaceuticals.

Some insulated containers have double walls (using the same technology as a Thermos flask), while others are lined with thermal blankets. This means that goods can be shipped through colder climates without the risk of freezing. Insulated containers are also equipped with filters to ensure the cargo is safe from outside air contaminants.

Methods of Container Shipping

Once you’ve picked the right type of container for your goods, you have to decide how you want it to be shipped. This will depend on how much cargo you have and how fast you need it to get to its destination.

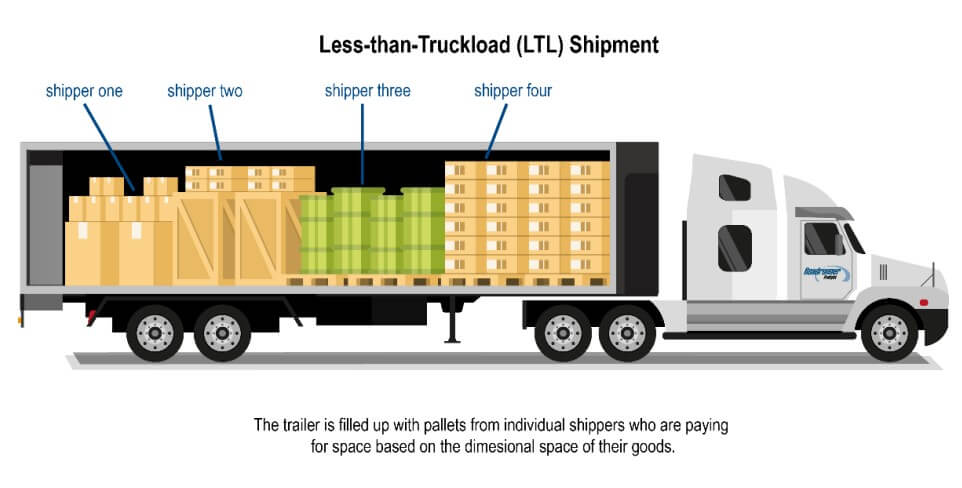

LTL

LTL stands for Less than Truck Load, which is an option when your shipment isn’t large enough to require the full capacity of a single truck. Rather than send the truck half-empty (meaning you’re paying for space you don’t use), you can use the LTL method to share freight with other shippers.

Source: ejet.com

If your goods only take up 40% of the available space, you just pay for 40% of the transportation fee. The remaining 60% will be filled by shipments from other companies. It’s a cost-effective option, but it’s slower as the truck has to stop and unload at several locations.

On a similar theme, Less than Container Load (LCL) refers to shipments in which you only take up (and pay for) a portion of a container. LCL is ideal when you’re trying out new products or shipping those with low demand. With both LTL and LCL, you won’t have any say on the type of cargo that’s traveling alongside yours, so it’s not a suitable method for items at risk from contamination.

FTL

As you’ve probably guessed, FTL (Full Truck Load) is a large shipment that requires a whole truck to carry it. You pay for the entire space, with no need to share with goods from other firms. That means the truck can go directly to its single destination, so it’s faster and less prone to complications.

The FTL method is especially suitable for fragile cargo, as the whole truck can be loaded in a way that keeps it safe—it doesn’t have to be rearranged to accommodate other shipments, or handled at every stop. There’s also no risk of the driver accidentally mixing up the deliveries.

Full Container Load (FCL) shipping is when an entire container is taken up by your goods. The standard size of an FCL shipment is six pallets in a 20-foot container or 12 pallets in a 40-foot container, so it’s perfect for large volumes or bulky items. If your shipment is valuable or delicate, it may be best to have your own container, even if it’s only partially full.

Source: freightos.com

Intermodal

An intermodal container is really another name for a large standardized shipping container. As we mentioned earlier, these are designed for “intermodal” freight transport—which means they can be used across various modes of transport such as rail, truck, and ship.

Intermodal containers make it easy to move the cargo between different transportation networks without unloading and reloading. They are fitted with simplistic holding mechanisms so that multiple containers can be stacked and positioned on rail cars, truck beds, and ship decks.

The International Maritime Organization (IMO) and other authorities have strict guidelines for using intermodal shipping containers. The load-carrying capacity is measured in terms of TEUs (Twenty-foot Equivalent Units) or FEUs (Forty-foot Equivalent Units). For example, a TEU refers to the amount of cargo that one 20-ft long container with a width of eight feet can hold.

Expedited

If you have a pressing deadline for the delivery of your goods, expedited shipping is often the best option for you. Freight forwarders offering this method will find you a ship that takes the fastest route between origin and destination, and priority is given to cargo belonging to customers who pay for expedited shipping.

Once the shipment arrives at a port, your containers are unloaded quickly and safely. They won’t have to wait around in the container yard—they’ll be processed and immediately taken onwards, often by airplane or small trucks to speed up the last part of the journey.

As you might imagine, expedited services are more expensive than standard shipping, especially in peak seasons, but you’re paying for the reassurance that your shipment will get there on time. With air freight rates currently sky-high (excuse the pun) due to a lack of capacity, more companies are offering expedited ocean shipping to cater for customers who need fast transportation.

Pros of a Shipping Container

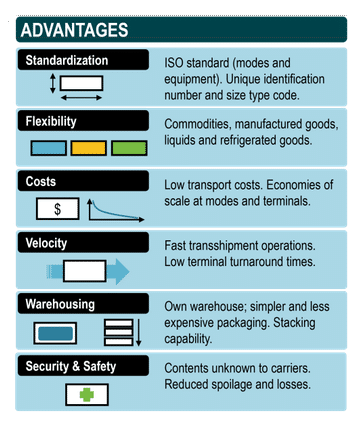

Source: transportgeography.org

We’ve already outlined some of the pros of using shipping containers—they’re strong, secure, easy to transport and store, and can be used over and over again for a wide variety of goods. Let’s take a closer look at some of the major advantages.

Storage

One of the advantages of shipping containers is that they are suitable for a huge range of goods, which are stored safely inside as they travel over sea or land to their destination. They are spacious enough to handle oversized or heavy cargo, and you can get different shapes such as tanks and drums for liquid or flammable products, as well as specialized versions for cars or livestock.

Standard sized containers are easy to stack, whether they’re traveling on a ship or a truck or awaiting loading or unloading at a port or yard. There are even collapsible containers that take up less room when they’re empty.

Plus, containers are really useful as temporary storage at your warehouse or distribution center, for example if you’re running low on capacity due to a large order. You can keep the goods dry and secure until they’re needed.

Safety

Containers are also a safe means of transportation, thanks to their overall strength and ability to withstand adverse weather conditions. As long as your container has passed the required inspections by the CSC or another authority, you can trust it to keep your goods in optimum condition.

Containers guard against things like water leaks, airborne contaminants, and fluctuations in temperature. They are also very stable, no matter whether they are carried by sea, road, or rail. If yours is the only shipment in the container, you can ensure the goods are stacked in the best way to minimize any risk of damage.

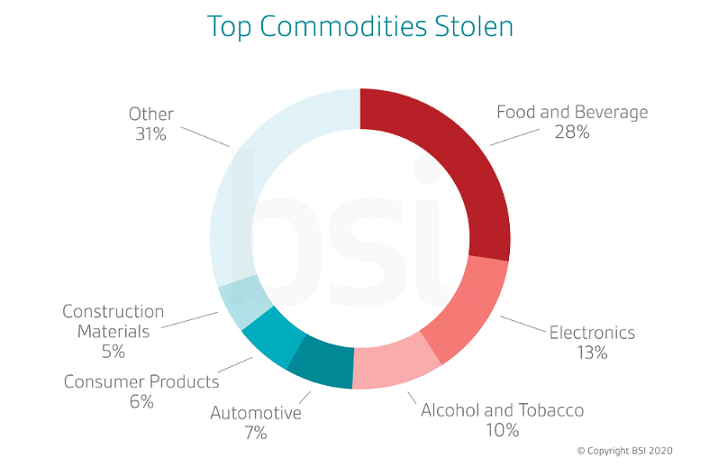

Once goods are loaded into the container, it is sealed completely, and is usually transferred without being opened (unless there is some reason for the authorities to check the contents). This vastly reduces the risks of theft or tampering.

Source: commons.wikimedia.org

Flexible and Durable

Shipping containers are versatile and flexible, especially the flat rack and collapsible versions. Because of their standardized dimensions, it’s easy to move them between different transport networks and locations. Standardization also means they are accepted and recognized internationally, making the world your oyster for the import and export of goods.

Due to their strong and durable construction, they can be used over and over again. And containers that have reached the end of their goods-carrying lifespan can be recycled and reused for other purposes. People buy them and turn them into sheds or workshops, bars and diners, and even affordable living accommodation—while architects use them to create unique structures.

Affordable and Effective

Containerization is the most effective way of shipping goods over long distances—it’s less expensive than air freight and you can transport heavier cargo. Standardization makes transportation faster and more affordable, because multiple containers can be stacked together on one vessel.

It also streamlines the process of loading and unloading, as containers are easier to handle than multiple irregularly-shaped shipments. This also minimizes the time spent transferring goods between different types of transport.

Due to faster delivery and transfer of goods, as well as reduced waste, you can achieve cost savings throughout the supply chain. And since containers are tracked using unique codes and computerized systems, you’ll know where your shipments are at all times—so you can update your inventory and your customers.

Modified

Shipping containers are already highly secure. Their cargo doors typically have an in-built locking mechanism using steel bars and a “cam and lock system” which makes them difficult to break into. However, if you are transporting high-value goods, you can choose to enhance security by modifying your container.

Container padlocks, sometimes called shutter padlocks, are a simple and affordable way to boost security. Because they’re made from hardened steel with a thick heavy-duty shackle, they are a lot tougher to break than the standard type of padlock, even if the thief is using bolt cutters.

Source: ttclub.com

Another option is a lock box, which is designed to be used in conjunction with a padlock. The box is made from strong steel and placed over the padlock to prevent tampering. Authorized personnel are still able to undo the padlock by inserting the key via the underside of the box.

There are also alternative shipping container locks such as latch guards or code-protected entry locks. If you’re planning to use your containers as extra storage at your fulfillment center, you could consider adding further precautions such as an alarm system, CCTV, or robust fencing.

How Much is the Average Cost for Shipping Containers?

That’s a tricky question. While each shipping company will have its own tariffs, the price of containers fluctuates depending on factors like distance, quantity of shipments, the time of year, and the construction material of your container. (Wooden containers are typically the least expensive, while steel containers cost more because they are more robust.)

Shipping prices will also be affected if you need to use containers that don’t fit the standard dimensions, such as cylindrical tanks or open-top containers where the cargo prevents them from being stacked efficiently.

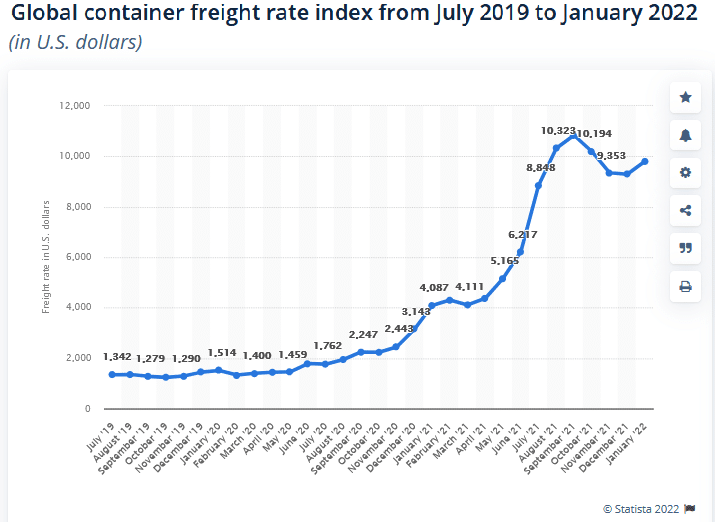

The shipping industry uses various indexes to track the average cost of container shipping along major trade routes. One of these is the Drewry World Container Index, which is maintained by a maritime research and consultancy company and uses the latest container shipping market data to give businesses an idea of costs.

Drewry measures the cost of shipping a full 40-foot container load on routes such as Shanghai to Los Angeles and Rotterdam to New York. The average cost hit a record high of $10,800 in September 2021, and at the time of writing, it stood at $9,468 per 40ft container—that’s $6,486 higher than the five-year average of $2,982.

Source: statista.com

Similarly, the Freightos Baltic Index has the average at $9,628 per FEU. Their data shows that shipping a container from China or East Asia to the US west coast will set you back $15,218, and the price from North Europe to the east coast of North America is $6,964.

Recent supply chain problems have included COVID restrictions at ports in China, with delays compounded by the Chinese New Year holiday. According to Drewry, the turmoil of the last year and a half is going to continue for longer than the industry initially thought, meaning that container shipping rates are likely to remain high for a while yet.

That’s why it’s important to reduce costs wherever you can—read on for inspiration!

Other Benefits of Using Brightpearl

We couldn’t possibly list every single benefit of Brightpearl in this post—you’ll have to check out the website for yourself and explore the details of each feature. Here’s just a taster of what you can expect:

Final Thoughts

Yes, shipping container costs are on the high side right now, and we don’t know how long that’s going to last. But container shipping is still a great way to transport your goods across long distances—containers are stable, safe, and secure, and their standard dimensions make them easy to move between different transportation networks.

If you choose the best type of container and shipping method based on the type and quantity of your goods, you can get them to their destination on time and in optimum condition. Accurate demand forecasting and inventory management are essential to make sure you use your container space wisely and cost-effectively.

With Brightpearl’s advanced tools, you can reduce shipping container costs by ensuring that each container is filled efficiently—and you can also streamline your fulfillment and shipping processes for further cost reductions, including the ability to manage all your suppliers and carriers in one place.

Thanks to smart automation, Brightpearl customers save two months a year on average, as well as lowering labor costs by 50% and reducing human errors by 65%. Getting things right every time means you can reduce the cost of returned or incorrectly delivered shipments, and keep your customers (and shipping partners) happy.