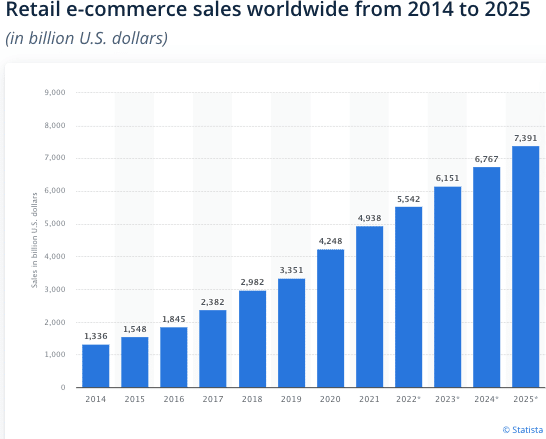

The past few years have seen continual growth in industries like e-commerce.

In 2021, retail e-commerce accounted for more than $4.9 trillion in sales. Studies project that this number will increase to nearly $7.4 trillion in 2025.

More customers are shopping online whether B2C, B2B, or DTC. This rapid growth has generated a change in customer expectations when it comes to things like delivery times and product availability.

It can be a difficult task for medium and large businesses like yours to stay agile with market trends and evolving customer behavior. Luckily for you, the tactics and tools for inventory management are continually improving to keep up with demand.

Making optimized changes that can be universally applied to your sites across the globe is not an easy task. Inventory management software solutions, though, are streamlining all steps of the logistics supply chain, including the all-important area of warehousing.

This means you and your management team can streamline the process of modernizing your inventory management strategy. Inventory management tools can help improve the efficiency of your warehouse operations; with modern technology, implementation is easier than ever before.

Source: statista.com

What is inventory management?

The inventory management process involves the oversight of products from the supplier to the consumer. This includes the procurement of raw materials (when applicable), receiving stock, item storage, order fulfillment, shipping, and delivery of all products sold that generate revenue for a business.

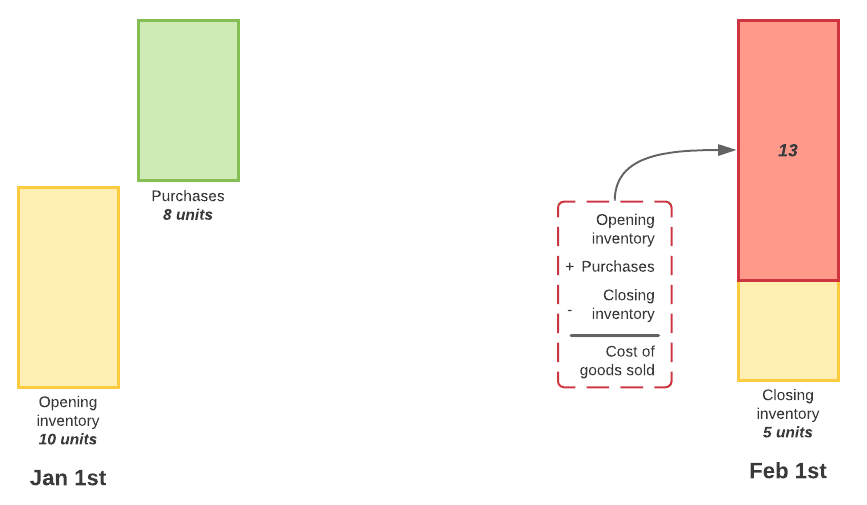

Inventory management deals with overall stock levels no matter where they’re located within the business. This information allows management to forecast demands and calculate reorder levels to avoid stockouts and overstocks. It can also help to give a business relatively accurate (or better) ideas of stock on hand and account for the costs of goods sold (COGS).

Importance of implementing inventory management in your warehouse

Inventory control is important to all areas of supply chain management. For many businesses, like those in retail, keeping your inventory in order is most important in your warehouses. This is because the warehouse is where the actions of receiving, storage, fulfillment, and shipping take place; those are many areas where money can be lost and human error can lead to dissatisfied customers.

Inventory management system vs. warehouse management system

At first glance, inventory management and warehouse management might sound like equivocal terms. This is not the case.

Inventory management systems are designed to handle any of the processes related to inventory for businesses of any size. This includes not only the ability to count inventory but also perform forecasting, ordering, receiving, and stock allocation. Any business that deals with the movement of stock can gain benefits from inventory management software.

A warehouse management system (WMS) will have many of the same main inventory capabilities, but the scope of the system is more focused on what’s happening in the warehouse. For starters, any business looking into a WMS solution will need a necessary component: A warehouse! WMS are typically part of larger systems like ERP platforms.

As such, a WMS is a common solution used by larger companies and enterprises. These tools can integrate seamlessly with other business systems. However, ERP systems can be quite complicated, inflexible, and not tailored for retail.

An alternative for warehouse and inventory management software is a retail operating system like Brightpearl which has the market-leading features for both.

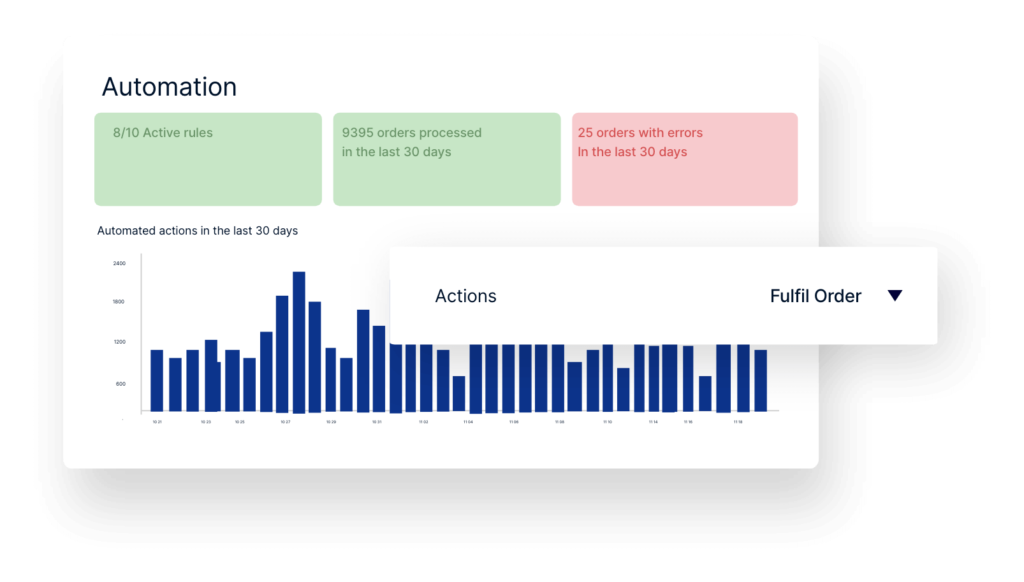

Brightpearl is built for retail and can handle all the functions of a WMS and much more. Other platform components include the Automation Engine, Inventory Planner, POS, dropshipping functionality, and other systems tailored for hyper-scalable commerce.

Advantages of a warehouse inventory management system

Businesses like yours likely have many warehouses scattered in diverse locations. Effective inventory management not only helps you form a strategy for optimizing your warehouses, but also lays out a single unified system that maintains business continuity.

There are many advantages to using an inventory management system in your warehouses:

Enhances order fulfillment accuracy

When it comes to your customers, they don’t care what excuses you have for how or why they received the wrong order—or, worse, nothing at all.

Each negative experience risks bad online reviews and the loss of potential customer lifetime value (CLV). With an inventory management system, your team will be guided to fulfill orders with much greater accuracy.

Accurate inventory will prevent ordering errors that cause customer frustration. Many redundant and automated systems can be put in place to ensure almost nothing leaves the warehouse that isn’t perfect.

Improves warehouse productivity

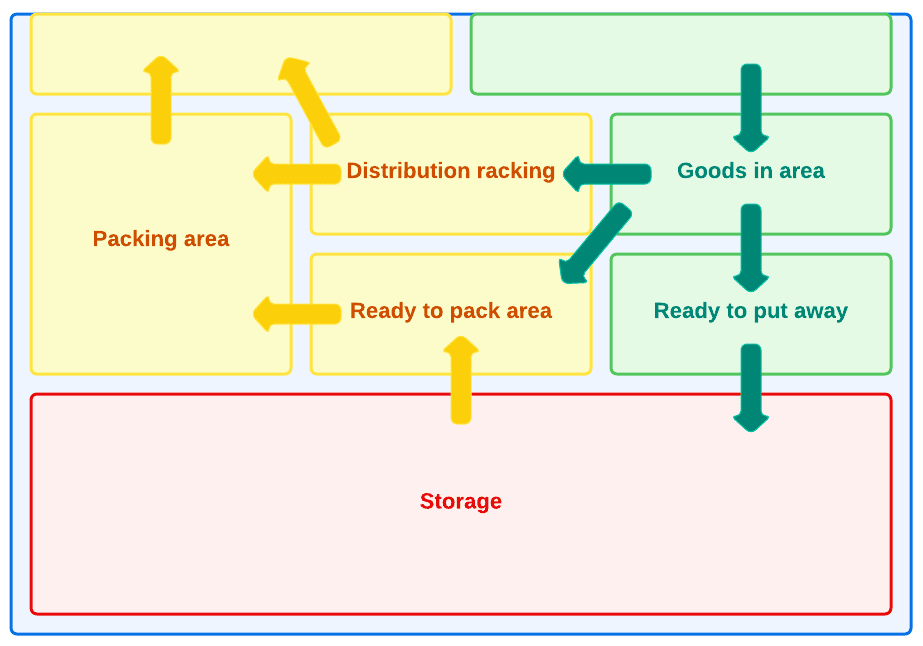

Systems that can manage your warehouse processes improve productivity in several ways. Firstly, they can help you plan the optimal warehouse layout for workflow. This means items are stored in an intuitive way that makes sense for your team. For example, your bestsellers will be placed closer to the packing stations.

Another way productivity is improved is by guiding your team through the picking process. Pickers will be able to get all of the items they need in the shortest route without having to double back.

Warehouse automation features also eliminate manual tasks like data entry, label creation, purchase order generation, and advance shipping. This saves your warehouse team loads of time so they can focus on more important tasks like picking and fulfilling orders.

Rapid shipping and deliveries

With an inventory management system, you can set up automated and optimized workflows for things like shipping and delivering products. With Brightpearl, labels will be created instantaneously and couriers or shipping teams will be scheduled at the quickest time possible for both inbound and outbound logistics.

Optimized picking and warehouse layouts will empower your team to fulfill customer orders more quickly. And that means orders can ship faster. Nothing will wow your customers more than speedy shipping and short delivery times.

Cost efficient

An efficient inventory management strategy (and system) helps you to maximize your monetary resources.

They can help you calculate optimal reorder points and stock levels. More effective use of your warehouse space means less money spent on holding costs. Additionally, a boost in warehouse productivity means your team can get more done in less time, saving on the wage bill.

Increases customer satisfaction

Nothing disappoints an online consumer more than to arrive at the perfect item and only then find out it is out of stock. Stockouts are a necessary evil in retail, but can be all but eliminated with the right inventory management software system. You will avoid losing potential sales with much-improved product availability to meet customer demand.

Better accuracy and speedy delivery can only mean one thing: A better customer experience. Your customer loyalty will skyrocket, orders become virtually error-free, and shipping works like a dream. It doesn’t end there for improved customer satisfaction, either. The cost efficiency and increased team productivity mean you can pass off the savings to your customers as well.

Types of inventory management systems & solutions

Like many things in business, “inventory management” is an umbrella term that covers many types of strategies and systems. There is not a one-size-fits-all approach to inventory and warehouse management. Businesses like yours will likely find that a combined approach suits your needs.

Periodic systems

One type of manual or physical inventory counting method is known as a periodic inventory system. These intermittent counts are conducted at least once a year, but are usually not done more than quarterly. This is because manual counting is a daunting and arduous task for businesses of any size.

In a periodic system, you aren’t limited to only performing full inventory counts all at once. Instead, you can use cycle counting to tackle a full inventory audit. This lets you take on a full count one slice at a time. Bear in mind that this approach may introduce more chances for human error like double counting. It also won’t give you a complete snapshot of your stock at any given time.

Perpetual systems

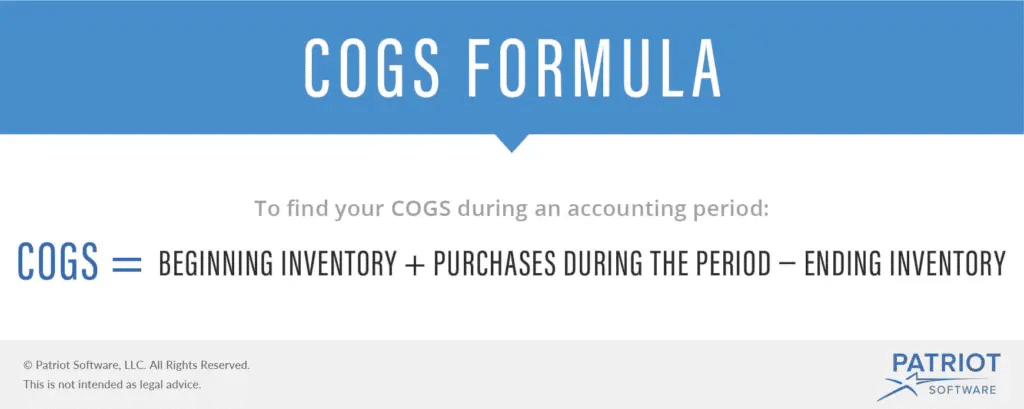

A perpetual system is exactly like it sounds: A never-ending inventory count. With this type of inventory tracking, every good received or sold is updated continuously to reflect accurate stock levels and update accounting metrics like COGS.

Source: patriotsoftware.com

A perpetual inventory system can only be implemented effectively with a software solution. Businesses will use tracking tools like barcode scanners or radio frequency identification tags to continuously monitor and update their inventory in real-time. This type of system all but eliminates the need for manual periodic inventory audits.

Having access to the most up-to-date inventory information possible makes it easier to calculate accounting figures and optimize processes like replenishment.

On-premises inventory management software

Inventory management software is the crucial foundation of modern stock oversight and control. The sun is setting for on-premises inventory management solutions. However, these legacy-type systems are still more efficient than using something like spreadsheets for tracking SKUs, purchase orders, and all the other elements of inventory management.

SaaS systems (cloud-hosted software)

Software-as-a-Service systems offer an on-demand warehouse inventory management service for everything from small businesses up to large enterprises. These services are provided in the cloud on vendor servers or via third-party infrastructure like Amazon Web Services (AWS). SaaS inventory and warehouse solutions can typically be used by any team members with a network connection.

Cloud-hosted software is normally paid for as a monthly or annual subscription. This type of inventory management software works great for businesses because of the flexibility it enables and the value it offers; you only pay for what you use. These platforms come with a range of capabilities for inventory, supply chain, shipping, and order management.

Warehouse management system

Many software solutions either are or include warehouse management systems, also known as WMS. These software tools are modules that are either standalone or included as part of broader software suites that can be on-premises or hosted in the cloud (far more popular today).

Barcode systems

Barcoding systems work hand in hand with inventory management tools. While they still require manual tracking by team members, they can quicken the pace of stock counts, transfers, and returns. Using barcode scanners also helps to eliminate human error from manual data entry.

RFID tagging software

Radio frequency identification is an alternative to barcode scanning as a method for inventory tracking. There are two main types of RFID tagging software: Active and passive.

With active RFID, the tags provide real-time inventory information as part of a warehouse management solution. They help to automatically provide data like inventory count and item location that stays up-to-date. This will continue working as long as the tag has battery power and is within range to communicate with the tag reader.

Passive systems for RFID tags must be activated by readers to send information. This is typically done when activated manually by team members using hand-held devices to scan units or pallets. Scanning can also be performed continuously by more complex and automated fixed readers that continuously send real-time information about your warehouse stock.

Inventory management techniques

Upgrading or improving your inventory management system can be done in a variety of ways, not least by choosing the right software solution. Several techniques, though, can help you along the way to better inventory fitness for your business:

Accounting methods

Probably the most important thing about inventory is that it is always coming and going (well at least if your business hopes to be viable). Without any protocol in place, pickers will always opt for the first matching item they can find. This is not always the most efficient way to manage your storage and holding costs. If you’re using a fulfillment center, you can expect the holding costs to increase the longer an item sits around the warehouse.

The most popular accounting method is first in, first out (FIFO). With FIFO, you can ensure a proper turnover of all stock to minimize the time each item stays in the warehouse. However, when products don’t have an expiration date or incur excessive holding fees, last in, first out (LIFO) suits speedy picking and order fulfillment.

You should choose a method that works best for your inventory and demand. You may find that a hybrid accounting method works best.

Demand planning

Sales projections are absolutely essential to inventory management in your warehouses. Demand forecasting is great to show the board, stakeholders, and even investors; and forecasting will also arm your team with the information to maximize your warehouse operations.

Inventory planning lets you set the right amounts of safety stock and guarantee inventory shifts promptly. Sales forecasting will also reinforce your reorder points so that you can make the most of your storage spending while meeting customer demand.

When converting to a new system, you may find the process difficult at first. But as you begin to collect and collate historical data, you can expect effective seasonal forecasting with increasing accuracy.

Dropshipping

If you’re reading this, chances are that your business is managing one or more warehouses as part of your business operations. An alternative that can eliminate some complexity is to go down the route of dropshipping. With this process, your suppliers ship the product directly to the customer. This lets you forego the cost of storage and fulfillment while still getting the items to your customers quickly.

Even if you have a swathe of warehouses, dropshipping can be a quick fix for unexpected demand or inflation in warehousing costs. It can be a useful technique for the short- or long-term; bear in mind, though, that you will have less control over product availability and order accuracy.

Safety stock

A simple yet effective way to buffer against uncertainty in inventory is with safety stock. This is inventory that you order and store in excess of your demand forecast.

This isn’t the most cost-efficient way to run your warehouse, but it will insure against things like supply chain disruption and unexpected demand spikes. For many businesses, it’s better to be safe than sorry. You will want to know the cost vs benefits of any safety stock; always focus on your highest selling items.

Best practices for inventory management in warehouses

Businesses like yours need the best tools for managing inventory in your warehouses. As with improvements to other areas of your organization, finding the best warehouse inventory management solution is only the first step. You and your team will also need to set yourselves up for success by doing things the right way.

Here are some best practices to follow:

Use money-saving options

The end-game of inventory management should be increasing your ROI. This means cutting out the fat and setting up operations to run effectively on the fewest resources possible. To get things right, you will need to peruse all of the options and methodologies available. If you can operate on a just-in-time basis, adopt something like cross-docking. You can then eliminate a huge amount of costs that would be spent on inventory storage.

You will also want to make sure you pick the right processes for your business and the products you sell. For example, both wave picking and batch picking can help a warehouse team run like a well-oiled machine. Each one can help to keep wage bills low and lead to quicker picking and ultimately more efficient order fulfillment.

If you sell mostly a few items or only small items, then batch picking will maximize the output of every single picker on your team. If you get much more diverse orders, then wave picking will be more advantageous. Wave picking will require more staff during a picking window, but they will be able to put more orders together in the same amount of time.

Make sure decision-makers consider all of the options, picking the ones that create the most value for the business. The best inventory management software should be able to guide your team throughout the process.

Link inventory levels and accuracy

According to a report by the ECR, 60% of inventory records are likely to be wrong at any point in time. Perhaps it goes without saying but by increasing the information available about your stock levels, you should see an increase in your reporting accuracy.

When you first implement your inventory management systems, you will be able to collect much more data than ever before. Processing and sifting through all of the data can feel overwhelming at times.

The most important thing is to make sure you are using inventory management software to streamline the tracking process. Make use of barcode scanners or RFID tags to make it easy for warehouse teams to account for every movement of every inventory item.

When done correctly, you will see inventory reporting with much higher accuracy. This achievement can be invaluable in saving time and money. Firstly, you can eliminate the need for rechecks and time-consuming manual counts. Secondly, with accurate counts, you can fully optimize your warehouse storage and reorder points (with the help of your inventory management software).

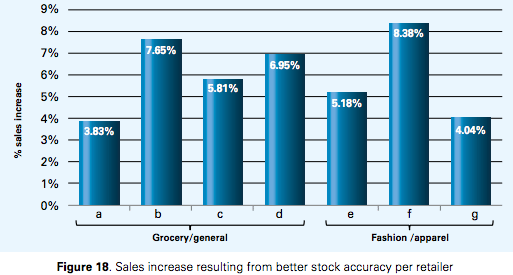

Source: cardiff.ac.uk

In the aforementioned report, Inventory Inaccuracy in Retailing: Does it Matter?, it was found that improving inventory accuracy led to increased sales of 4-8%.

Track high sellers

When you combine tracking technology with your inventory management system, the sky is truly the limit.

Use your inventory management tools to identify your best sellers seasonally and year-round. Place these items in the premier warehouse locations for rapid picking and fulfillment of orders. This should be your first priority with redesigning storage and depot layouts.

You should also use an inventory or warehouse management platform that lets you calculate and automate reorder points for your top sellers. Many businesses like yours already have a set level of safety stock for your best-performing inventory. While this can work fine, you can reduce your holding costs and COGS by using predictive forecasting.

Use analytics and reporting to track metrics like sales volume, usage, and shifting trends in demand for your products. With automated reorder notifications, you will have optimal holding stock and avoid stockouts during periods of peak demand.

Stay people-oriented

Once you get your inventory management software up and running, the data streams will start pouring into your central hub. Management and other decision-makers can quickly get caught up on numbers like COGS and gross margin, but don’t forget your actual warehouse team!

Every time an item has a scanned or recorded interaction, information like employee numbers or other identifications and the time of day are also recorded. Valuable team member data can help managers and supervisors better understand staffing needs for picking waves and shipping teams. It also lets them identify who are your rockstars and who may need coaching or guidance.

Implementing an inventory management strategy is all about running a lean operation, but it’s the people who are the heart of your business. Give your team members the tools they need and empower them to work well and productively.

Reorganize your floor plan

Chances are that you already have very experienced and well-trusted warehouse managers at each of your sites. They’ve likely been running an adequate or better system for many years now. Leadership doesn’t want to step on those, but it’s time to make it known that changes for improvement are on the way.

You can get the stakeholders on board by letting them know where you’re heading: Reduced costs and greater productivity. With your warehouse team, you must prepare and guide them for possibly big changes in the floor plan of each warehouse. But the good thing is that warehouse management software will make discovering the optimal layout a cinch!

A common practice to run an efficient warehouse is to use what’s known as the ABC method. With this practice, you classify and rank your inventory by turnover rates. Using the 80/20 model, Category A represents the 20% of stock that generates 80% of your sales volume. Each further category represents a lower share of turnover.

Focus on placing Category A products as close to fulfillment and shipping as possible. Once the work has been put in for a physical reorganization of the warehouse, the easy part follows. Your warehouse teams will be empowered with better workflows and a less arduous fulfillment process. And of course, that means more can get done in less time or with fewer labor costs.

Conclusion

In retail and e-commerce, inventory management is not something to be taken lightly. You may be mostly satisfied with your current stock control systems or you may be aware that they are floundering. Either way, optimizing your business with a better inventory management system will deliver cost savings and boost employee productivity.

It doesn’t end there. Your better stock availability, rapid shipping, and lower pricing will rake in lifelong and loyal customers. Inventory management in warehouse software will help your business rise above the throngs of your competitors and elevate your brand in the eyes of your customers.

Inventory management solutions make what was once a painful process easy. Dare we say even, a joy?

If you’ve made it this far, you should be well aware of the benefits and advantages of improving your inventory management. So the real question is, why aren’t you getting started today?