The success of a business is almost always reliant upon its ability to adapt to technology; regardless of industry, it’s always important to keep your company up to date and optimized for efficiency.

This couldn’t be more true for supply chain management, especially regarding warehouse and shipping fulfillment operations.

Supply chain is one of the most important aspects of brick-and-mortar retail, as well as e-commerce, so ensuring your warehouse is managed to full productiveness can be make or break for your company.

Below, I discuss what warehouse management is, how it’s changed over the decades, and finally, 6 tips to help you get on your way to modernizing your warehouse management. Hopefully, with these, you’ll be able to adapt your business to adhere to an ever-changing industry.

What is warehouse management?

Warehouse management is an important aspect of supply chain, and if your business sells a physical product or goods, chances are you have a good-sized fulfillment center or general warehouse to house your goods prior to distribution.

Warehouse management is the oversight and functioning of a company’s warehouse and its staff. This can include the management of tracking inventory, monitoring distribution of purchased goods, employee productivity, and general order fulfillment.

Though typically not client-facing, sometimes warehouses and distribution centers for the manufacturing and technology industries can also be a retail space; thus, warehouse management in these cases can also include sales and marketing.

Changes in warehouse management

With the shift in retail and other physical-good industries from brick and mortar to a more e-commerce focused, many aspects of warehouse management have gone through significant changes, in both organization and technology.

With the global shift to e-commerce, warehouse management has become even more complex and integral to supply chain management. Considering that goods are being purchased 24 hours a day, shipping demands have increased, requiring warehouses to work at an expedited rate.

Obviously, with these advances in customer demand, warehouses and distributions need to adapt their technology. In addition to warehouse management systems, mobile management systems, expense management systems, and other software have become integral to ensuring smooth operations.

While software is a significant part of keeping your warehouse up to date, warehouse robotics have been increasingly used in modern inventory management. With new innovations being pushed to market regularly, warehouses are able to automate certain stocking methods and eliminate human error.

Organizationally, team roles within a warehouse have changed dramatically in the age of automation. While certain roles now are replaced with robotics, new roles have been created in the quality control and operation of new machinery. In addition to this, general business operation, engineering, and management roles still remain essential to the upkeep of a well-running warehouse.

Ways to modernize your warehouse or distribution center

Check out the 6 ways you can improve upon your warehouse management through modernizing your current processes.

- Warehouse management systems

Arguably the most significant way you can adapt your warehouse management is by updating your current warehouse management system. Much like an ERP system, there are multiple aspects of WMS.

Warehouse management systems help offer visibility into your day-to-day operations by monitoring the movement of items within your warehouse and between locations, as well as product sorting.

Essentially, warehouse management systems automate the inventory process for your warehouse. So, ensuring you have an up-to-date, efficient WMS couldn’t be more prudent.

Selecting a WMS for your company is dependent on your organization’s size, function, and budget – where some smaller businesses might need a free, simpler software, an enterprise might need an all-in-one supply chain suite.

2. Layout and organization

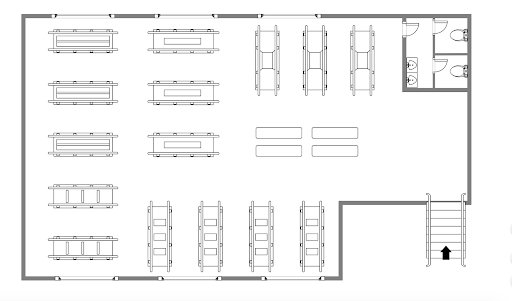

Organization is key to any business’s success, so creating an efficient layout of your warehouse is fundamental.

Assuming your warehouse has both large-scale machinery and a good-sized workforce, maximizing your space and minimizing waste is crucial to employee safety and productivity.

The details of your schematics are likely dependent on your industry, but making sure your space is optimized for both human activity and machinery helps keep both your warehouse and company safe and contemporary.

3. Going mobile

As with the client-facing part of your retail business, it’s important to adapt to changing times and technology by syncing a mobile application with your warehouse management system.

Migrating your warehouse management system and other software with a mobile management device can help mobilize (pun intended) your operations and prevent you from being bogged down to stationary computers. Through mobile migration, keeping track of warehouse operations, as well as employee communication and monitoring is far more straightforward.

Additionally, with BOPIS being a huge brick-and-mortar driver, ensuring your retail mPOS is linked with your WMS is essential to keeping your physical stores driving revenue.

4. Performance management

Employee performance is an excellent metric for measuring warehouse efficiency, so having a start-of-the-art performance management system that can track this helps keep your warehouse on the cutting edge.

Performance management software helps companies establish employee performance standards and allows managers to evaluate an employee’s job performance in relation to these standards. They can also be used to manage employee progress, performance, and development in relation to company goals.

Using a corporate PMS to promote meaningful discussions between managers and direct reports helps synchronize your team to be as functional and efficient as possible.

5. Modern Robotics

Technological advancements in robotics and automation are helping warehouses to operate almost autonomously, thus hastening order fulfillment and inventory stocking.

While there is a seemingly endless amount of new innovations in the field of robotics, the main ones relevant to warehouse management are as follows:

- Automated Guided Vehicles (AGVs) – move inventory within your warehouse. AGVs are utilized in procedures to replace manually-driven forklifts or pick carts, thus increasing employee safety

- Collaborative robots – mobile robots designed to help human workers perform their designated tasks in the warehouse. They function a lot like worker bees, and can do things like act as mobile storage bins or expedite order fulfillment.

- Articulated robotic arms – multi-jointed “limbs” used to handle products within distribution centers and warehouses.

- Automated storage and retrieval systems (AS/RS) – collection of computer-controlled systems that help automate inventory management and store/retrieve goods.

- Goods-to-person – G2P technology uses an automatic storage system to deliver items to stationary pick stations where human operators fulfill orders; very similar to AS/RS

6. Expense Management

Lastly, using an expense management system is crucial to monitoring all the financial ins and outs of your warehouse.

Your company’s facility management and upkeep, equipment use, operations, and labor force all require expense monitoring, so making sure the EMS you use is optimized and efficient for your business and accounting team helps keep everything running smoothly.

As with other software, different size companies and industries require different systems to meet their business standards, so it’s imperative to make sure you choose an expense management software best suited for your business needs.

Final thoughts

Warehouse management and supply chain overall is an ever-changing enterprise that requires you and your business to constantly adapt to new technologies and industry trends.

With these 6 tips on how to better modernize your warehouse management and operations, ensuring your inventory management and shipping fulfillment processes run smoothly can be one of the easiest parts of adapting your business standards for the future of retail and manufacturing.