Inventory tracking

If you’re running a retail business, whether large or small, your most fundamental responsibility is to ensure you have the right stock in the right quantities—and to do that, you need accurate inventory tracking as part of your stock management system.

With online retail behemoths like Amazon putting small businesses in the e-commerce sector under immense pressure, it’s never been more important to ensure that customers can get what they want with the minimum amount of effort. If consumers can’t find what they’re looking for, it’ll probably be quite easy for them to find it from a competitor—and that’s custom you’ll struggle to win back.

Effective inventory management, then, is of the utmost importance. Your inventory management system needs to be adequate to the task of anticipating fluctuations in consumer demand and maintaining stock levels appropriately. This is crucial to meeting rising consumer expectations, and maximizing customer lifetime value.

Of course, all this is much easier said than done. Indeed, 39 per cent of supply chain executives surveyed said that inventory management was the aspect of their supply chain which had been most impacted by the Covid-19 pandemic. Keeping on top of purchase orders, sales orders, and inventory levels is both tough and time-consuming. With the right inventory tracking methods in place, however, it needn’t overwhelm you.

In this guide, we’ll introduce you to some inventory tracking best practices. We’ll start by defining what inventory tracking is, then listing the key benefits and challenges involved. After that, we’ll discuss how to track inventory and look at inventory tracking compared with supply chain management.

Finally, we’ll conclude by outlining some of the best ways to keep track of inventory, including recommended inventory management software.

What does inventory tracking mean?

Inventory tracking, as the name suggests, refers to the tracking of stock levels throughout a business’s operations. These are continually in flux as customers make purchases and new stocks are brought in, whether to replace items that have been sold to those customers or in anticipation of changing demand patterns (as in the run-up to Christmas, for example).

There are two reasons why inventory tracking matters so much. Firstly, meeting consumer demand and secondly, the amount of money at stake. For businesses, it’s essential to streamline inventory management so that customers can find the right products and also to ensure that businesses don’t waste money on excess inventory.

Bigger businesses can devote more resources to warehouse management and inventory control. Some even have specific departments concentrating entirely on this work. For smaller businesses, this is obviously less realistic as an option. Nevertheless, tools such as inventory tracking software can help these small firms keep on top of warehousing, fulfillment, and more.

Inventory tracking systems play a central role in this regard. They provide businesses with real-time tracking of inventory items, helping them stay abreast of how many items of particular product lines are in stock and available for customers to order.

Some companies deploy barcode scanners so that orders are tracked as they go, whether they’re being paid for at a checkout or dispatched directly to customers from a warehouse.

Yet a lot of smaller firms and business owners still neglect inventory control, and this can cause major problems. For instance, employee theft and administrative errors will be harder to track. This leads to inventory shrinkage, which according to a study cost US retailers $61.7bn in 2020.

Source: Medium

Manual vs. automated tracking

If you’re a small business that’s just getting started in retail, and you don’t stock too many SKUs, you might choose to use manual methods to keep track of your stock.

On the face of it, tracking inventory with spreadsheets (or even pen and paper) is a low-cost practice. But unless you’re super-organized, manual inventory tracking is prone to errors that can actually end up costing you money.

For example, if you accidentally write an extra zero on your order, you’ll end up with excess stock—and if you forget to re-order in time for the holidays, you’ll have a stockout.

That’s why automated inventory tracking is a better solution. It’s far more accurate, giving you real-time visibility of inventory across multiple locations. It’ll sync the data each time stock levels change, and even generate reports for you.

The benefits of tracking inventory

Adopting an effective inventory management system has numerous potential advantages. For example, according to a survey conducted by business communications organisation GS1 (which first developed the barcode), using inventory tracker tech, such as radio frequency identification (RFID), can increase inventory accuracy to as much as 95 per cent.

With accurate inventory management and tracking, businesses can reap real rewards. Firms which know exactly how many products they have in stock and how many on order can save time as well as money. It saves them from having to go to the trouble of carrying out inventory recounts, thus freeing up staff to do more important and productive things. It also helps to prevent stockouts, which inconvenience customers.

By the same token, inventory tracking can also help to improve overall efficiency and productivity standards. Technology such as barcode scanners, QR codes, and even mobile apps can eliminate a lot of the more menial manual processes, so that members of your team can devote their energies elsewhere. This can also enable you to improve your workflow, customer service standards, and the general customer experience.

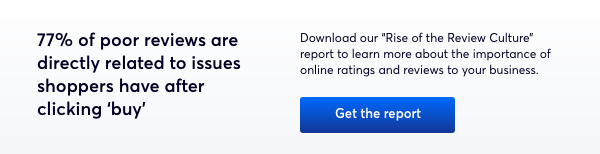

Indeed, the customer experience is hugely important, and it must not be overlooked here. Consumers who know they can rely on your business to provide them with the kinds of products they want, when they want them, are much more likely to keep coming back again and again. This is an effective way of fostering lasting, long-term customer and brand loyalty.

As well as all this, reliable and accurate inventory tracking can also ensure that warehouses are generally better organized. This is part of a virtuous circle: the better your inventory management, the more organized your warehouse will be, which in turn helps to improve inventory management even further.

For wholesalers and retailers alike, this can be hugely beneficial. The ultimate beneficiaries, of course, are consumers: good inventory management means that orders can be dispatched in a timely manner, which again leads to better customer experiences.

Case studies back these hypotheses up, too. For instance, global fashion retail chain H&M (which has a complex supply chain incorporating some 30 partners worldwide) found that introducing a centralized inventory management system helped to cut average lead times by between 15 and 20 per cent. Lower lead times reduce the risk of buying the wrong items.

Just-in-time inventory management is one technique which has been widely adopted in the retail sector. It’s designed to minimize waste and reduce costs by ensuring that goods are received as and when they’re needed and most in demand by consumers.

With just-in-time management, firms can improve cash flow (as less storage space is needed), reduce excess stock, and cut inventory holding costs. However, there are risks involved, too. Firms which adopt just-in-time methods must make sure they have accurate demand forecasts and a thorough understanding of customers’ purchasing habits.

The challenges of tracking inventory

While the benefits of inventory tracking speak for themselves, it’s important to be aware of the challenges involved as well. A solid understanding of these challenges is vital, as it can help businesses avoid falling victim to them.

It’s time-consuming

Although we noted earlier that inventory tracking can help save businesses time and effort, as well as money, it’s worth noting here that inventory management can be quite time-consuming in itself. It’s something that becomes more and more complex as businesses expand into more channels and sales grow, which means there’s more to analyze and track.

It goes without saying that for retail entrepreneurs, there’s no shortage of demands on their time. Multichannel retailers have plenty on their plate, whether it’s recruiting and training staff, undertaking marketing campaigns, or scoping out opportunities for expansion. Inventory tracking is one more responsibility on top of all that.

Keeping track of items isn’t always easy

Another challenge of inventory tracking is that orders are frequently moving about from place to place. It’s not as simple as leaving them in a single warehouse until customers need them. Items can be moved between more than one location before they get to a consumer.

As items are transported between different locations, it inevitably becomes more challenging to keep track of where they are and how many of them there are. This can have problematic knock-on effects. In particular, it means there’s a risk of inventory shrinkage (through loss or theft, for example), unfulfilled or late orders, and incorrect financial records.

Bigger inventories are harder to manage

We’ve already alluded to this point, but bigger inventories are more complicated to manage. Obviously, ambitious entrepreneurs will always be looking for opportunities to grow. But as sales increase, so will inventory turnover, and managing this is undeniably tricky.

You might find yourself carrying multiple varieties of the same product type, so the task here is keeping track of all of these – in all their respective sizes, colors, styles and so on. As well as managing their pricing, while ensuring that your business has enough of each to meet customer demand. Scaling up inventory tracking is therefore one of the toughest hurdles for growing businesses to overcome.

How do you effectively track inventory?

There are various methods of tracking inventory, some of which are more effective than others. Let’s take a look at some of them here.

Pen and paper

Some businesses (usually long-established smaller firms) still use manual pen-and-paper methods, writing down the details of each transaction on a card system. However, this is clearly a less than optimal way of doing it, and the majority of businesses have long since moved on from such methods.

Excel spreadsheets

Some businesses simply use Excel spreadsheets to keep track of inventory. This is okay for small companies dealing with very low order volumes, but it is likely to prove inadequate even for medium-sized businesses. As your business grows, you’ll probably soon find that these spreadsheets aren’t up to the task.

There are a number of problems with using spreadsheets to track inventory. As we’ve just observed, tracking large quantities this way is very difficult. Human error in record-keeping is all too common. Businesses also lack real-time data, which again makes it much harder to keep an accurate record of inventory. Forecasting is also made more difficult as there is less historical data at hand.

Google Sheets inventory tracking

Although spreadsheets are a step up from paper copies, you still have to enter information manually. But if you use Google Sheets, there’s a way to automatically update your inventory every time it changes. You can set this up using Zapier, which connects your apps and moves information between them based on your own rules.

Basically, you can set a “trigger” action that tells the spreadsheet to update itself. In this case the trigger would be a new response in Google Forms. Once you create a new Form from within your Sheet and add the fields you’d want to update, a new tab is automatically created so that every time you fill out the Form, your responses will be routed there.

Click here for full instructions on how to track inventory in Google Sheets.

Third-party logistics

Another option is to outsource order fulfillment to a third-party logistics firm and thus let it take care of the whole process. As these firms handle your orders, they also have responsibility for your inventory, packing, and shipping orders to customers. They can also provide detailed, real-time inventory reports, and keep tabs on exact inventory levels.

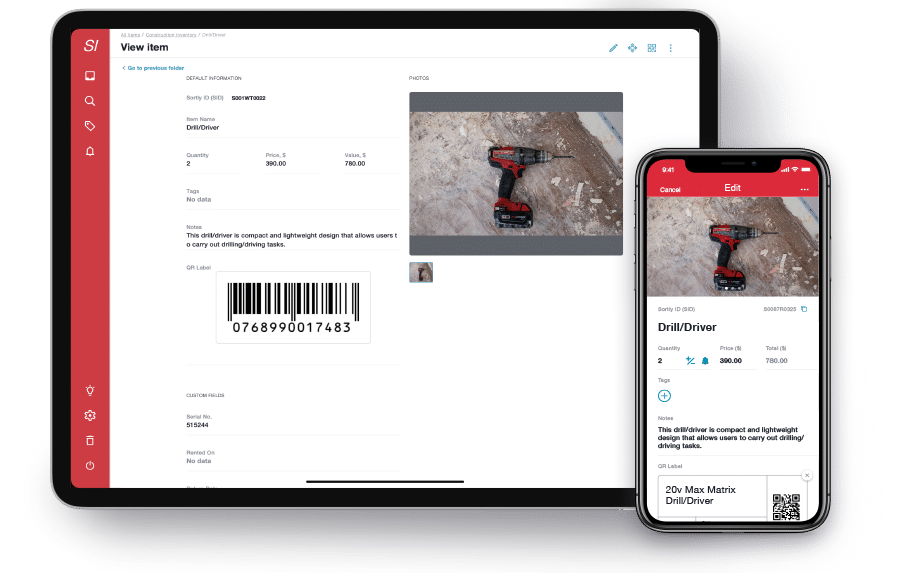

Mobile apps

Increasingly, many businesses (including many startups) are using iOS and Android apps instead of spreadsheets. Apps such as Sortly, Stock Control, and Goods Order Inventory are widely used among small firms. However, businesses can often find these apps somewhat limiting as they expand and their needs grow more complex.

Source: Sortly

Inventory tracking software

Inventory tracking software provides a much more comprehensive overview of inventory. Warehouse operatives can scan 2D barcode labels as orders are processed, providing an instant record of which items are in stock, which items are running low, and which are overstocked. This is just one of the ways in which automation is making life easier for businesses and their workers alike.

Other advantages of inventory tracking software include quicker auditing, enhanced mobility, cycle counts, and more accurate reporting. Compared to the pen-and-paper or spreadsheet method, this opens up far greater possibilities for businesses and provides them with a much more detailed understanding of their inventories.

An advanced inventory tracking system, by having more data and allowing for in-depth analysis, can also allow for data-driven inventory planning. Excess stock and overselling are part of the most common problems; businesses need to anticipate demand to maximize sales without having too much cash tied up in slow moving products.

Inventory management software with inventory demand planning functionality can help to prevent this, with detailed historical data helping businesses to better understand fluctuations in customer buying patterns. Businesses are given a clearer idea of what they need to reorder at specific points in the business cycle.

Inventory tracking and supply chain management

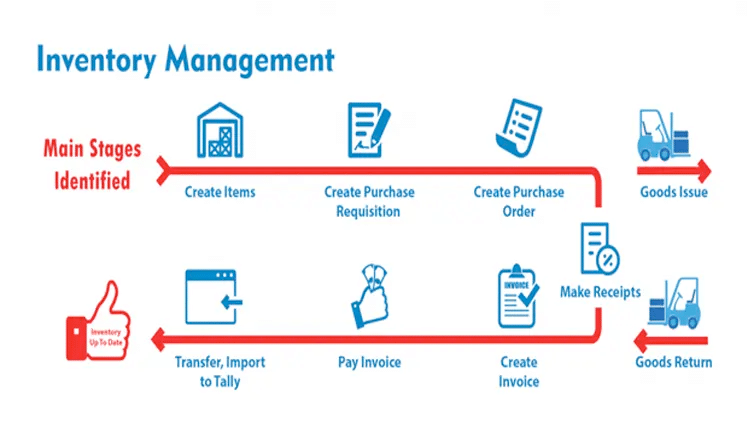

Effective inventory tracking is essential to good supply chain management. Inventory management is one vital aspect of supply chain management, and there are different elements to tracking inventory. It’s not just a matter of keeping an eye on how many products you have in a particular place at a particular time.

You also need to track inventory from suppliers, to track customer returns (because these are inevitable) and to monitor damaged goods (ditto). If your inventory management methods fall short in any one of these areas, it’ll be your customers who will likely suffer – in the form of delayed deliveries and incorrect or incomplete orders.

To ensure efficient supply chain management, you must ensure that your understanding of your customers’ wishes and your forecasting methods are up to par. In other words, being able to anticipate what consumers will want, and when they’ll want it. Seasonality is a crucial consideration in this regard. We all know about the Christmas rush, but this isn’t the only seasonal fluctuation you should be braced for.

You should also be careful to make sure that your supply chain partners are a good fit. Maintaining good supply chain relationships is indispensable to keeping your business ticking over. And, most importantly of all, making for a better all-round customer experience. Make sure you carry out thorough research before choosing partners.

What is the best way to keep track of inventory?

Following on from our previous point, choosing the right inventory management solution is also of crucial importance. Brightpearl’s retail inventory management software, which is built-in to the wider Retail Operating System, enables you to ensure you have enough inventory in the right places in order to provide your customers with what they need at all times.

It provides comprehensive functionality and a centralized overview of your operations, allowing you to manage inventory, orders, purchasing, accounting, point of sale, suppliers and more – across multiple channels and locations.

With Brightpearl, you can also get real-time insight into sales performance, costs, and profitability, as well as undertaking smart planning based on previous data. It also makes it easy to automate repeat inventory control tasks and set customized rules so that goods are automatically routed to a warehouse, or replenished when they’re running low.

Keeping your customers happy is a challenge at the best of times, and it’s only growing even more challenging. With the right inventory management software, you can enjoy a whole heap of benefits – better productivity, greater efficiency, clearer visibility – and your customers, without even realizing it, will be the ones who really benefit.