Inventory management requires maximum visibility, optimum productivity, and complete accuracy, all while trying to satisfy customers and keep costs as low as possible. It’s not an easy task, but it’s crucial to get it right.

We’re going to show you some tried-and-trusted techniques and best practices for effective inventory management, which you can use alongside software solutions to make sure you always have just the right amount of stock to fulfill your orders.

What is Inventory Management?

Inventory management, sometimes called inventory control, is the process of handling and tracking your inventory as it moves in and out of your warehouse or distribution center. It’s an important stage in the supply chain, as it shows you how much stock you have and where it is at any given time.

The ability to track inventory from purchase to sale means you can manage inventory levels correctly, and make informed decisions about reordering so that you don’t end up with too much or too little stock. Strong inventory management also helps you identify and respond to trends and peaks in demand.

In the fast-paced world of modern retail, it’s no longer viable to track your inventory with spreadsheets and manual data entry—you need advanced software to streamline processes and ensure there are no human errors. This could be a standalone inventory management system, or part of a full Retail Operating System like Brightpearl.

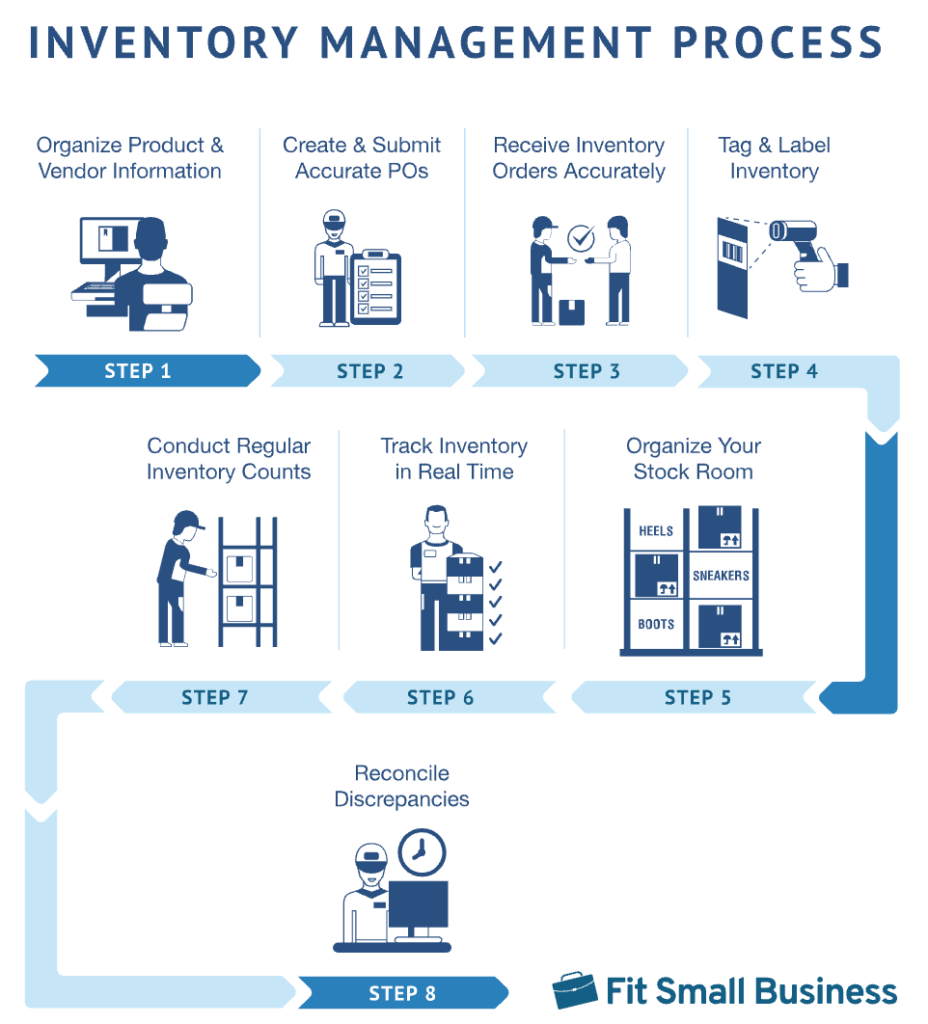

Source: fitsmallbusiness.com

Types of Inventory

The term “inventory” covers all the items your company either uses in production or sells to consumers. In retail businesses it is often referred to as “stock”, but the two terms have become interchangeable.

Inventory can be divided into a number of categories, including raw materials, components, and finished goods. These are the four main types of inventory:

Raw Goods

Raw goods are the materials or substances a company uses to create or finish products. This might include wood, metals, plastics, or fabrics, which are usually unrecognizable from their original form once the product is complete. For example, a roll of silk could be turned into a batch of dresses.

Raw materials can be subdivided into two categories. Direct materials are those used in the final product (such as the wood used to manufacture a cabinet), while indirect materials are used during production but not included in the final product (such as the oil used to maintain machinery).

Components are also used to create and finish products, but they are usually complete items in their own right, such as the screws used to hold furniture together.

Work-in-progress (WIP)

Work-in-progress inventory describes partially-finished items that are currently in production, usually being assembled at a dedicated workstation. This type of inventory includes raw materials or components, packing materials, and the cost of machinery, labor, and overheads.

A WIP is basically a piece of inventory that has been combined with human labor but has not yet reached finished goods status. For example, it might be a dress that still needs the zip to be added.

Ideally, you want to complete this stage as quickly and accurately as possible, since you can’t recover your investment until the product has been finished and delivered to the customer.

Source: safetyculture.com

Finished Goods

Once a WIP is complete, it becomes part of the finished goods inventory. These are items that are ready to be sold—for example, the finished dress in its cellophane wrapper, ready to be delivered to a store or mailed to an online customer.

“Finished goods” is a relative term, as a seller’s finished goods may become a buyer’s raw materials, although this is not usually the case in retail. When finished goods are sold, they are called merchandise.

It’s vitally important to calculate your finished goods inventory on a regular basis, so that you can avoid the problems of overstocking or understocking.

Maintenance, Repair and Operations (MRO) Goods

Maintenance, repair and operations goods are materials and equipment used to support the production process or the day-to-day maintenance of the business—they are not part of the final product.

MRO inventory can include safety wear such as face masks, gloves, and goggles; cleaning equipment and supplies; office supplies such as stationery; hardware like computers, printers, and barcode scanners; and any tools or equipment used to carry out repairs.

MRO is not always recognized as part of an inventory—but it makes sense to keep a log of these items, as they have a cost attached. And if you fail to order enough of these items, you could face problems with the smooth running of your operations.

Importance of Inventory Management

Inventory management is a crucial part of retail and manufacturing operations. If you don’t maintain a tight grasp of the state of your inventory, your other processes (order fulfillment, shipping, demand planning) will quickly fall apart.

Knowing how much inventory you have, in each location, is crucial. Accurate records mean you can list the correct items for sale online, allocate the right amount to each channel, and provide real-time information on availability.

Source: spendedge.com

Smart inventory management also enables you to carry out accurate demand forecasting and avoid the pitfalls of excess stock and out-of-stocks. The inventory management process is closely linked to warehouse management, since a 360-degree view of your stock helps you reduce mistakes in picking, packing, and quality control.

Any inaccuracies, whether it’s ordering the wrong amount of stock or sending the wrong item to a customer, carry a corrective cost in terms of both money and labor. Mistakes will also damage your reputation with customers. But with a robust inventory management process in place, you can:

Avoid Spoilage

Spoilage is when perishable items go bad, or spoil, while they are part of your inventory. This can happen because the goods haven’t been stored correctly, or because you’ve accidentally ordered too much stock and it passes its expiration date before you can sell it.

Full visibility of your inventory will help you to ensure perishable goods are refrigerated as soon as they arrive at your warehouse, or otherwise stored in the optimum conditions. You’ll also gain awareness of exactly what’s on your shelves, how long it’s been there, and how long it should last. (And you can also watch out for any accidental damage or theft.)

Make sure you pick the right method for moving inventory, and communicate it to all staff. The FIFO (First in, first out) method ensures that the oldest inventory is sold first, which makes sense for comestibles. LIFO (Last in, first out) assumes that the newest inventory will be sold first. It’s not ideal for perishable goods, unless your latest delivery has a shorter-than-expected expiration date.

Avoid Dead Stock

Poor inventory turnover and inaccurate demand forecasting can lead to the problem of dead stock. Also known as obsolete stock, these are items that prove difficult to sell. It might be that you’ve simply ordered too much safety stock, or you failed to notice that a particular product line has declined in popularity.

The longer this inventory sits on your shelves, the more it will cost you in warehouse storage and insurance. Plus, it’s at increased risk of spoilage, damage, or theft. You might have to do a flash sale to get rid of it, which means you won’t get as much profit—and if you really can’t sell the items, you’ll probably have to pay to recycle or dispose of them.

Reduce Storage Costs

It’s pretty obvious that the more inventory you carry, the more it will cost you in warehouse overheads, insurance, and staffing. Holding a smaller amount of stock will reduce your inventory costs, but you need to make sure that you have enough to fulfill all your orders.

It’s a fine balance—and it can only be achieved with effective inventory management. The ability to accurately predict demand will show you how much storage space you need, and ensure that you’re not paying for empty shelves. Using the proper inventory management techniques will also help you to make the best use of your warehouse space.

Increase Cash Flow

Inventory is your company’s biggest asset—but while it’s sitting in your warehouse or distribution center waiting to be sold, it’s tying up your working capital. It’s critical that you have cash on hand to invest in other parts of their business, or as a safety net to get you through an unforeseen crisis.

Good inventory management leads to better cash flow management. For instance, if you order the right amounts and track product performance, you can make sure you’re only spending money on inventory that’s going to sell, which keeps cash moving through the business.

It will also ensure that you don’t lose out on sales (or customer loyalty) through stockouts and errors, and you can plan ahead by setting enough cash aside for buying further inventory. Certain inventory management techniques can be used to free up cash flow—see the Just In Time section below.

10 Techniques in Inventory Management

There are many methods you can use to improve inventory management, but we’ve selected ten of the best techniques (which are even more useful when you combine them with an advanced software system like Brightpearl).

1. Bulk Shipments

Bulk shipping is a popular technique in inventory management, largely because it’s usually cheaper to purchase and ship goods in bulk. Fewer shipments mean lower costs, whether the items are coming to you from a local supplier or being shipped from overseas.

Bulk shipments are most suitable for goods with high, predictable customer demand, so you need to be sure that the items will sell. The technique works well for staple products with long shelf lives, but not goods with shorter expiration dates or those that could be easily damaged.

The downside is that a large inventory makes it difficult to adjust your strategy when demand changes. You’ll also have to spend extra money on warehousing— but these higher carrying costs are usually offset by the money you save from buying in bulk and selling the items quickly.

2. ABC Inventory Management

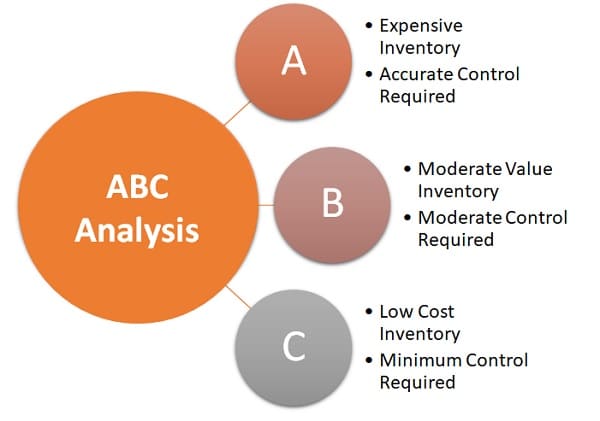

ABC analysis involves categorizing your inventory into three groups based on things like inventory value, popularity, and cost significance. The method involves an ongoing process of data collection and evaluation, which will help you to carry out accurate demand forecasting.

Items categorized as A are high-value goods that contribute the most to overall profit (around 80% of your revenue). They will only make up about 20% of the inventory, but you’ll need to ensure you always have some on hand so you don’t miss out on potential sales.

Source: mbaskool.com

B items are of moderate value and moderate in number, representing roughly 15% of your revenue and 30% of the total inventory. Category C covers items of small value (5% of revenue) with high sales frequency. Making up 50% of your inventory, these are vital for overall profit.

Not all products have the same value, so the ABC system helps you decide which ones deserve more attention and resources. For example, you would take extra care when storing high value items, and you might need to adjust the pricing of items that are struggling to sell. However, you won’t need to spend time and effort worrying about products with steady demand.

3. Backordering

You might think of backorders as something to be avoided, and that’s definitely the case if they’re unplanned! However, sometimes a company will decide to take orders and receive payments for out-of-stock products— and some businesses continue to take backorders until they generate enough sales to place a large order with a supplier.

Intentional backordering has several advantages as long as you get the logistics right. It helps you increase sales and boost cash flow, as well as reducing holding costs and the risk of being left with excess stock. On the flipside, the longer fulfillment times can cause frustration among customers.

The process is simple for a one-off (you just create a new purchase order and give the customer an expected arrival date), but errors can occur if you’re placing backorders regularly. That’s why you need a smart inventory management system that gives you real-time information and lets you keep customers in the loop. Brightpearl’s integrated POS system can take backorders as well as showing stock availability on all channels.

4. Just-in-Time

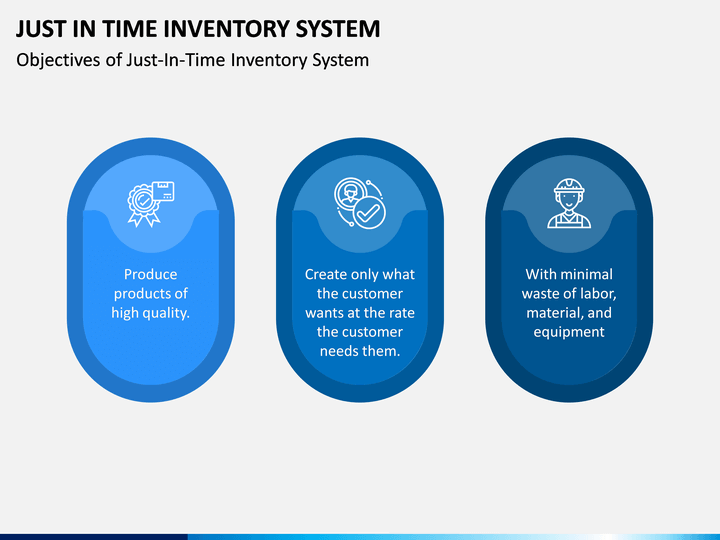

Just in time inventory (JIT) is when a business replenishes its stock at the latest possible moment—just in time to avoid a stockout. The aim is to drastically reduce holding costs and improve cash flow, with the added advantage of eliminating the risk of dead stock.

Source: sketchbubble.com

However, this technique gives you no room for error, and you can run into problems if a supplier is suddenly unable to deliver the goods. You may end up paying more to source the products from elsewhere, as you don’t have time to hang around for the best price. And if you can’t get them at all, your customers will not be impressed.

If you’re going to keep stock levels low, you’ll need great relationships with reliable suppliers, an efficient order fulfillment system, and a deep understanding of customer demand and its likely fluctuations. Again, inventory management software is critical to making JIT work for you.

5. Consignment

Selling on consignment is when a vendor or wholesaler agrees to place goods in the hands of a retailer, but still retains ownership until the product is sold—which is when the retailer pays for the inventory. It requires a strong relationship between the two parties, as neither gets paid unless there is a sale to a customer.

For retailers who are unsure of demand, it allows you to offer a wider range of products without tying up capital by having to pay upfront. You can even return any unsold goods at no cost to you. Consigned inventory is often stored in dedicated warehouses owned by the wholesaler, located on or near your property for easy access.

The wholesaler bears most of the risk in this model—so why would they want to do it? Well, it enables them to test out new products, collect useful information about product performance, and hand marketing responsibilities to the retailer.

6. Dropshipping and Cross-docking

Dropshipping is a fulfillment method in which goods are shipped directly to the customer by a manufacturer or wholesaler, rather than from your own inventory. You never handle the product, which means you don’t have to pay for storage or track it through your warehouse.

Source: businessmodelanalyst.com

Some retailers rely entirely on dropshipping, while others only use it for some of their orders. The main benefit is reduced holding costs, but shipping fees can be expensive—and you’re putting your reputation in the hands of a third party. If customer orders go wrong, you’ll still be the one who gets the complaints!

Cross-docking also reduces or eliminates the need to hold inventory. When a delivery arrives at your premises, the goods are unloaded directly onto outbound transport vehicles for delivery to stores or customers. The downside is that you might not get to check the quality of the products, although some companies do have special areas where deliveries can be sorted and stored briefly until the outbound shipment is complete. Brightpearl’s barcode scanning technology can speed up this process and ensure the right items go to the right place.

7. Inventory Cycle Counting

Cycle counting is where you perform a mini-audit on a small amount of inventory instead of doing a complete stocktake. It’s more efficient, as it can be carried out using less resources and with minimal disruption to your everyday operations. This means you can do it more often.

This technique is an important aspect of inventory management, because you can check that your inventory records tally with what you actually have in stock—and you can address any discrepancies quickly. However, it’s less comprehensive than a full stocktake, and may not account for seasonal fluctuations.

It’s up to you how often you do a cycle count and how much stock is involved. Count products when they’re at their peak, check the highest-value items more frequently, and make sure you vary your schedule to avoid theft.

There are several variations you can use. Control group cycle counting is where you count the same items multiple times in a short period, to highlight any errors in the technique. If your warehouse has a large number of similar items, random sample cycle counting helps reduce disruption. And there’s ABC cycle counting, as discussed earlier (where A items would be counted more often).

Source: instructorbrandon.com

8. Stock Review

This inventory management strategy is about reviewing stock availability and how it matches up with your predicted future needs. Small businesses might try to monitor supply and consumption manually, but it’s far more efficient and accurate if you use advanced inventory management software.

It’s important to define your minimum stock level, otherwise known as PAR (Periodic Automatic Replacement) level. This is the optimal amount of an inventory item that should be in stock at all times. You should also set your reorder point, which is the optimum time to request new inventory from the supplier to avoid a stockout. Remember to factor in expected demand, lead time, and potential supplier delays.

Economic order quantity, or EOQ, is a formula used to calculate the ideal order quantity a business needs to purchase for its inventory. With variables like total costs of production and demand rate, the formula helps you minimize buying by identifying the greatest number of product units to order. The aim is to reduce related costs and free up cash that would otherwise be tied up in inventory.

From the supplier’s point of view, the minimum order quantity (MOQ) is the smallest amount of set stock they’re willing to sell. Inventory items that cost more to produce would usually have a smaller MOQ, while cheaper items with more cost-effective production have a larger MOQ. If a retailer can’t purchase the MOQ of a certain product, the supplier won’t sell it to them.

9. Kitting Process

Kitting, or product kitting, is an inventory management technique in which a selection of individual, but related, products are assembled into a single package. This might be done to streamline shipping costs, or to create a bundle of certain items (for instance, those that are not selling well individually).

E-commerce fulfillment companies like Amazon use this model to gather multiple goods ordered by a customer and combine them into as few shipments as possible. It is also used by subscription box retailers, where products are bundled together based on a theme. In manufacturing, it’s used to organize and assemble parts.

Kitting is a good way to optimize workflows and make the best use of warehouse storage space, thus saving time and money. As well as reducing shipping costs, fewer shipments are better for the environment, too.

10. Six Sigma Practice

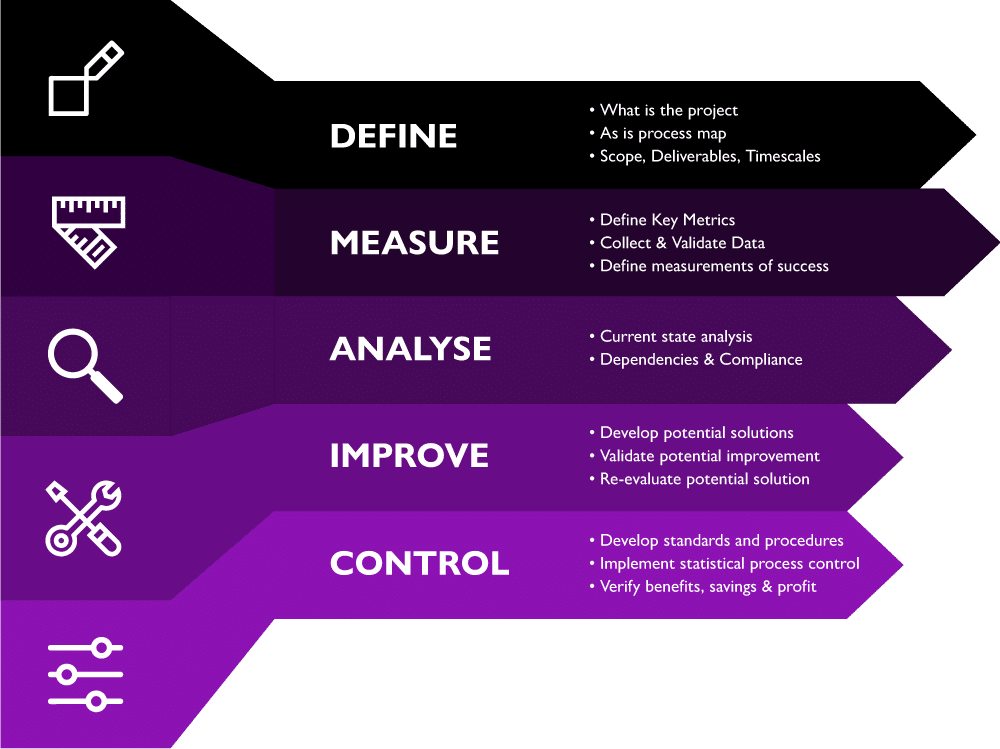

Six Sigma is a quality-control methodology often used in inventory and supply chain management. It provides a set of tools to help companies work faster, make fewer errors, and generally avoid waste and variation—all of which should improve your profits.

Waste is defined as anything that adds cost but does not add value to the product or service. For example, if you carry more inventory than you need, you are wasting money, space, and employees’ time. Six Sigma aims to reduce excess inventory and obsolete stock, which can prove costly for business owners.

Variation describes a lack of uniformity in a product or service. This includes defective products as well as problems with mis-picks or delayed delivery, which results in unhappy customers. Variations in the way you manage your inventory can lead to a disorganized warehouse with stock going missing or getting damaged through inappropriate storage.

To follow the Six Sigma principles, start by defining the issue you want to solve (it needs a clear metric), and measure the current state. Then you analyze what’s causing the problem, and come up with an action plan to fix it. Run some pilot tests to see if your solution eliminates the problem, and track a metric to verify that your new process works.

Source: leanconsulting.com

Benefits of Inventory Management

Successful inventory management brings a ton of benefits, from increasing your profits to fostering customer loyalty. By maintaining full visibility of your stock, you can reduce the risk of selling out, ensure you don’t end up with obsolete products taking up valuable warehouse space, and make accurate predictions about future demand.

You’ll also reduce costs by streamlining workflows for greater productivity, and ensuring employees can easily locate, pick, and pack the right products for each order. As a vital link in the supply chain, good inventory management helps you build strong relationships with suppliers and shipping partners in order to get the best prices.

Using the techniques shown above, combined with advanced inventory management software such as Brightpearl, you can take the strain out of inventory management—even as your business expands into omnichannel retail and multi-location fulfillment.

Increased Sales

Keeping accurate inventory records is important for many reasons, but did you know that it can actually increase sales? Real-time data about stock levels helps you to accommodate orders properly, whereas errors can screw up the whole process.

Let’s say you accidentally miss a batch of products in your cycle count. Your inventory records will show that there’s not enough to fulfill an order and the system will decline to process it, causing a lost sale. On the other hand, if your records say there’s more stock than you actually have, the system will accept an order—but you won’t be able to fulfill it.

When your records match the reality, it’s far easier to satisfy customers and keep them coming back for more. That’s why it’s vital to use smart software instead of manual data entry. Plus, automating your processes will help you to move products faster and replenish them ready for further sales.

Source: corporatefinanceinstitute.com

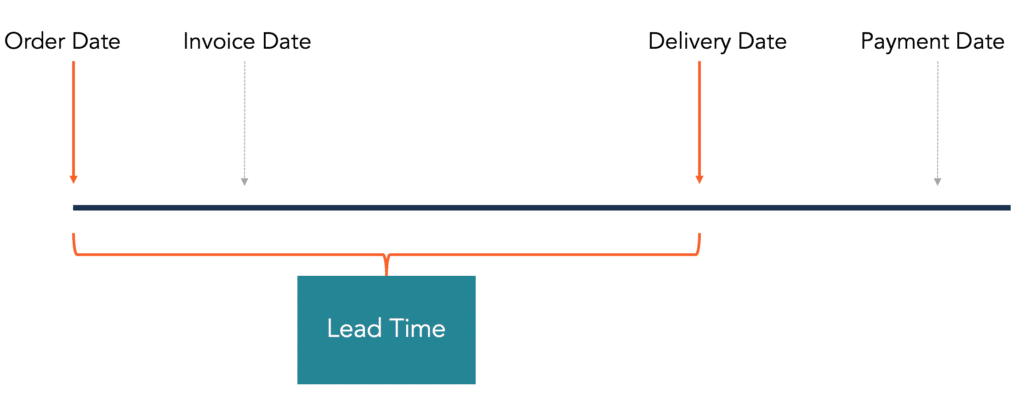

Short Lead Time

It’s simple—shorter lead times give you more profit. For one thing, you can keep customers happy by delivering their parcels quickly, so they will be keen to order from your company again. Increased order fulfillment boosts your cash flow, while shorter lead times give you extra flexibility to respond to new trends in the market.

Your inventory won’t be hanging around in the warehouse for long, so there’s less likelihood of it being damaged, spoiled, lost, or stolen. And you can establish a regular system for stock replenishment to avoid stockouts.

To reduce your lead times, you’ll need reliable suppliers based as locally as possible. The more suppliers involved, the longer the lead time is likely to be—but if you manage your supply chain efficiently and build lead time expectations into your contracts, you can keep things under control. It’s also good to speed up your internal processes with automation.

Information Transparency

Inventory management is only going to work effectively if everyone has access to the latest information—which includes stock level updates, order status, returns data, and shipping details. Your staff need to log all inventory changes on a centralized system, so that you have a complete overview of the whole process at all times.

As well as tracking inventory and orders yourself, you need to be able to collaborate with other departments like accounts and marketing, share information with suppliers and logistics partners, and pass on shipping details to customers. Easy access to customer data and sales performance stats is crucial for demand planning.

It’s good practice to make everyone accountable for good inventory management, and to house your information in one central place—such as Brightpearl’s comprehensive retail operations platform.

Source: marketingcharts.com

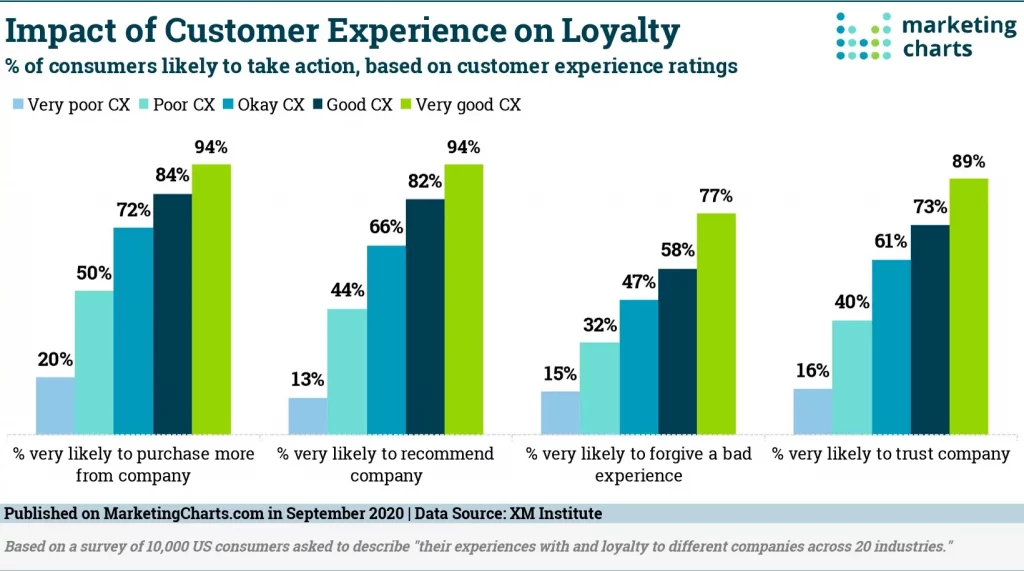

Customer Loyalty

Without proper inventory management, it’s difficult to guard against problems like stockouts, delayed deliveries, damaged or faulty goods being sent out, or discrepancies with stock availability on your website. All these things are hated by customers, and will quickly make them turn elsewhere.

But if they can easily see the availability of their preferred items, and if they always receive parcels on time and in optimum condition, they will develop a favorable opinion of your business. They will be happy to use you again, eventually becoming loyal customers and even brand advocates. And they’ll pass on word-of-mouth recommendations to their friends, and write positive reviews.

Low Costs

Smart inventory management helps you reduce costs in a number of areas. When you’re confident about customer demand, you can lower the cost of warehousing by only carrying the optimum amount of stock needed to fulfill your orders (you might use techniques such as just-in-time and selling on consignment).

You can also eliminate obsolete inventory and the costs associated with spoilage, damage, or having to dispose of unsellable goods. By improving your processes, you can avoid the corrective cost of mis-picks and delayed deliveries, as well as potential lost sales due to stockouts.

With advance planning, you can find the best shipping deals and optimize your transport costs, while maintaining good supplier relationships will also help you negotiate the best prices.

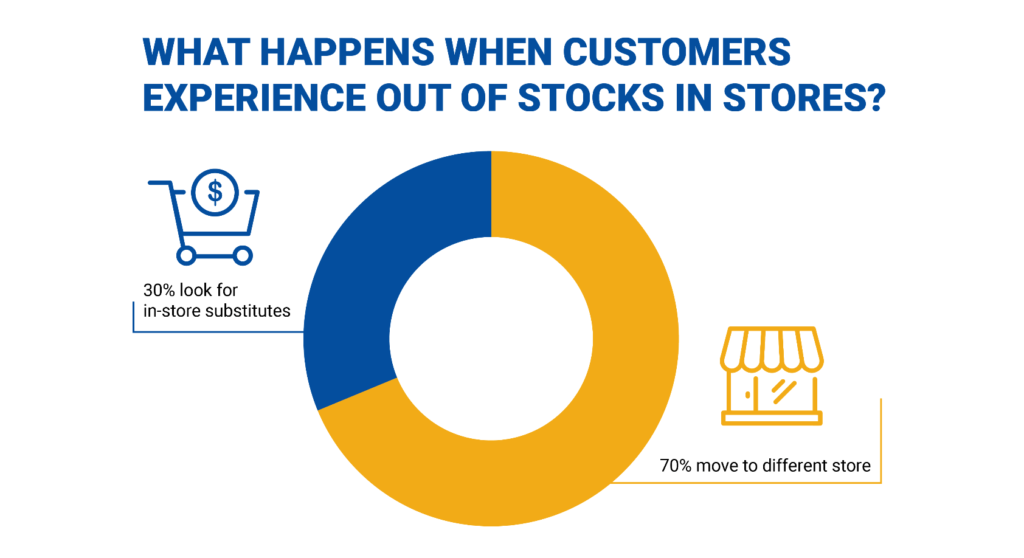

Decreased Stockouts

With full visibility into your inventory, you will drastically reduce the risk of stockouts. Accurate records and real-time data show you the contents of each warehouse and store at any given moment. You won’t list items as being in stock when you’ve actually run out, which means you won’t disappoint customers.

Source: explore.movista.com

Apart from losing the goodwill of your customers, stockouts can be costly because you’ll be forced to purchase more of the in-demand product from wherever it’s available—without waiting for the best price. And you might have to pay more to transport it from further away if your local supplier doesn’t have it.

Smart demand planning, based on accurate analytics and reporting, will also help decrease stockouts. And strong relationships with suppliers will mean they prioritize your orders, and they’ll let you know in advance if there’s a supply chain issue.

Best Practices in Managing Your Inventory

Best practices include focusing on accuracy and cost-efficiency at every stage, communicating regularly with suppliers and customers, and using the right technology.

Even with the best inventory management system in place, you may encounter the odd speed bump. Make sure you plan ahead for unexpected issues such as a supply chain breakdown beyond your control, a warehouse disaster, a sudden spike in demand, or a shortage of raw materials.

Cloud-Based Inventory

Controlling your inventory management via the cloud is a super-efficient practice. With records stored digitally instead of on paper, there’s less chance of them going astray, and automated systems mean a reduction in human error. Plus, the central system updates automatically whenever there’s a change to your inventory.

Cloud-based inventory also encourages transparency and information-sharing, since all employees can access the data. Your team can log in from any device, anytime, anywhere—which means that staff in different warehouses (even across the globe) can all use the same system and get real-time information on stock levels and order status.

Cloud-based software can also save you money, as there’s no need to install computer hardware and maintenance is handled by the provider. It usually operates on a SaaS (software as a service) model, where you pay a monthly subscription rather than buying the system outright. There’s no capital expenditure, which helps with cash flow.

Accurate Stock Records

Accuracy is everything in inventory management—without it, the whole supply chain falls apart. You need to know exactly what you have and where it is, so that you can order the correct amount of stock and easily spot issues with spoilage or shrinkage.

We’re not just talking about inventory in your warehouse or on the shelves of a brick-and-mortar store. You’ve also got to factor in inventory that’s currently in transit, in production, or going through the returns process. There’s a lot to juggle, and you can’t do it manually.

With the right software, you can log all the information in a centralized system. The data syncs across channels each time a sale, transfer, or return happens, so everyone’s in the loop. For example, Brightpearl’s POS (point of sale) tool shows real-time stock availability as well as housing useful customer records.

Cost-Efficient Purchasing Procedures

Cost-efficient purchasing ensures you’re not spending money on inventory you don’t really need, or buying from suppliers that fail to give you the best deal. It’s about ordering the right amount at the right time from the right vendor.

To do this successfully, you’ll need to look at historical sales reports from previous years and peak seasons, so that you can decide how much to order and when. Brightpearl lets you specify the most affordable suppliers and automatically places an order when you’re out of stock, and you can also generate a single invoice for multiple purchase orders.

Split Inventories into Categories

To make life easier, it’s a good idea to divide your inventory into groups—both for stocktaking purposes and for assessing turnover and profitability. This gives you a clearer idea of which items are performing well on which channels, and which product lines could be jettisoned.

You could choose to use the ABC analysis method, or batch tracking (where you track items as groups rather than individually, in order to save time and easily trace defective items back to their original batch).

As we said earlier, categorizing inventory shows you which products need the most attention, so that you don’t spend too much time and effort on items that are not especially important to your business. It also means you can store goods in the most suitable part of the warehouse, such as placing frequent sellers nearest to the packing station.

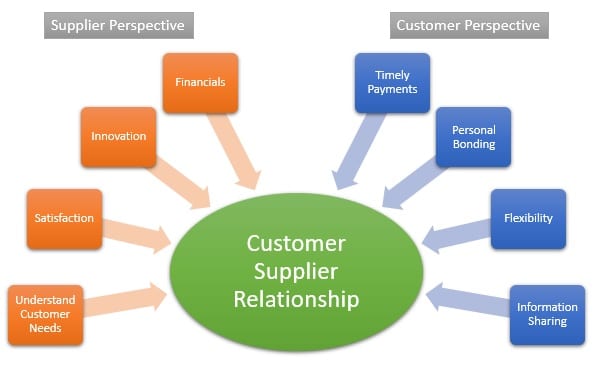

Harmonious Relationship with Suppliers

Developing positive supplier relationships is an important part of inventory management, as it will help you to negotiate the best deals and encourage them to make your orders a top priority. When you share information and generally communicate well, they’ll be more willing to work with you to solve any problems that might arise.

For example, let your supplier know in advance when you’re expecting a spike in sales so they can adjust production. And ask them to tell you if they’re running behind schedule so that you have enough time to seek out an alternative. Discuss any issues and try to find a solution together.

Supplier management is made simpler with Brightpearl’s centralized system, which features a web portal to eliminate manual tracking and data entry. You can keep an eye on your relationships, and determine whether it’s time to ditch an unreliable supplier in favor of the ones who always come up with the goods.

Source: mbaskool.com

Monitor Everything

The only way to keep your operations running smoothly is to monitor the whole system and check it’s working as it should. That way, you can spot any issues and make improvements. For instance, if it’s taking pickers too long to locate items, you might want to reconfigure your warehouse layout. You should also check your par levels and restock points several times a year to ensure they fit in with current demand.

It’s worth asking for feedback from your staff—do they have the right tools and workflows to do the best job possible? Customer feedback is also important, so encourage them to tell you about delays, faulty items, or incorrect product listings (and the good stuff, too!).

Regular Inventory Checks

This is probably the most important task of all. If you don’t keep a close eye on stock levels, you’re at risk of stockouts, dead stock, spoilage, misplaced items, and theft. Regular inventory reconciliation is critical, using advanced software to cross-check your records with inventory on the shelves.

You can also use perpetual inventory management, where you count the goods as soon as they arrive to make sure the supplier has sent the right quantity. Barcode scanners and optimized warehouse and stockroom layouts will make this easier.

A complete stocktake or physical inventory count should only be performed once a year (typically at the year-end to tie in with tax returns). It’s time-consuming, and can be very disruptive to the running of your business. Plus, it can be tricky to find the root of a discrepancy when you’re looking back at an entire year. That’s why regular cycle counts and unscheduled spot checking are useful.

Bottom Line

Inventory is your company’s biggest asset, so it’s vital that you look after it properly. Not only will this save you time and money, it will ensure customer satisfaction and loyalty. Effective inventory management means you can maintain optimum stock levels, forecast future demand, and work with suppliers and shipping partners to get the best prices.

To properly manage your inventory, you need the right software: Enter Brightpearl. The retail operations platform integrates smart inventory management tools with warehouse management, order management, fulfillment and shipping—plus built-in CRM, POS, analytics, and accounting.

You can sync data from all your sales platforms and channels, both online and offline, and see real-time updates any time your inventory changes. The Automation Engine speeds up everything from data entry to generating purchase orders, and Brightpearl is scalable and flexible enough to support you as you grow.