As your retail business grows, so does the need to manage your warehouse as efficiently as possible. Without streamlined processes in place, you’re risking serious problems such as stockouts, spoilage, delayed deliveries, and unhappy customers.

You can’t possibly keep on top of complex warehouse operations with clunky spreadsheets or time-consuming manual processes—which is exactly why warehouse management software was invented.

We’ll take you through the different types of tools and their benefits, explore some aspects to consider before making a purchase, and explain why Brightpearl is the best solution (not just for warehouse management, but for all your other retail operations, too).

What are warehouse management tools?

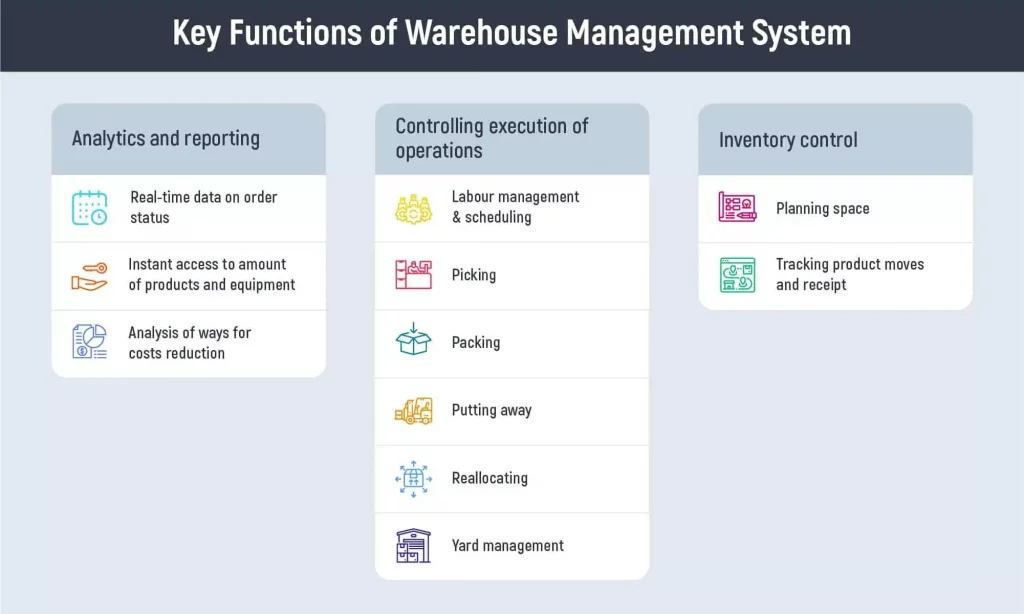

Warehouse management tools help businesses to optimize their warehouse operations, in order to maximize efficiency, address common challenges, and support the rest of the supply chain. The tools are designed to streamline workflows, and might include inventory tracking, automation for picking and packing, and workforce management.

These individual tools are usually presented as a software solution called a WMS (Warehouse Management System), which has robust logistics capabilities and gives you a 360° view of your warehouse operations—making it easier to achieve omnichannel and multi-location fulfillment.

WMS solutions help you ensure that goods and materials move through your warehouse or distribution center in the most efficient and cost-effective way, and maximize your use of labor, equipment, and warehouse space.

The global market size for Warehouse Management Systems was valued at $3 billion in 2021 and is expected to grow at a CAGR of 15.3% to reach $8 billion by 2028. In a 2021 survey, 83% of respondents reported that they are using a WMS.

Source: issuewire.com

Types of warehouse management tools

Warehouse management solutions fall into two categories: Standalone tools and integrated systems. The option you go for will depend on the size and type of your business, but let’s have a look at the key differences:

Standalone

As you might expect, standalone WMS tools are set up purely for warehouse management, rather than for other segments of the supply chain.

That can be a good thing, as you’ll know that the software has been designed specifically for that task. Tools like Fishbowl may be more appropriate for wholesale and manufacturing businesses, while companies offering third-party logistics might use something like 3PL Warehouse Manager.

However, bear in mind that you’ll likely need to buy additional tools for other processes, such as order fulfillment and supplier management, which could end up costing you more than investing in an integrated system. Some WMS software (such as HighJump) will integrate with other tools (for example, ERP systems like Oracle Netsuite or SAP), but it won’t be as seamless as an all-in-one solution.

Integrated

Integrated systems like Brightpearl feature a dedicated WMS feature alongside a range of other tools for processes such as inventory management, order management, shipping, accounting, and CRM. All the tools work seamlessly together, with data syncing between the modules for real-time visibility.

You may be thinking that it’s a lot more expensive to use an all-in-one platform, but it all depends on what you want to achieve. If you only need WMS capabilities, it might make sense to buy a standalone tool. But as your business grows, you may find you need the extra functionality. Plus, even if the monthly cost is higher, you’ll soon make savings in terms of productivity and error reduction.

Source: scnsoft.com

How do Warehouse Management Systems work?

Although many WMS systems do interact with other aspects of the supply chain, their main aim is to control what happens while goods or materials are at your warehouse or distribution center. The software will track items from the moment they arrive from a supplier, to the moment they are loaded onto a truck for delivery to the end-customer.

Warehouse management solutions optimize all the processes involved in warehousing, starting with receiving and putaway. The system then covers the picking, packing, and dispatching of goods, as well as tracking shipments and returns. It can also include auditing to monitor inventory levels, although this may be done by a separate inventory management system.

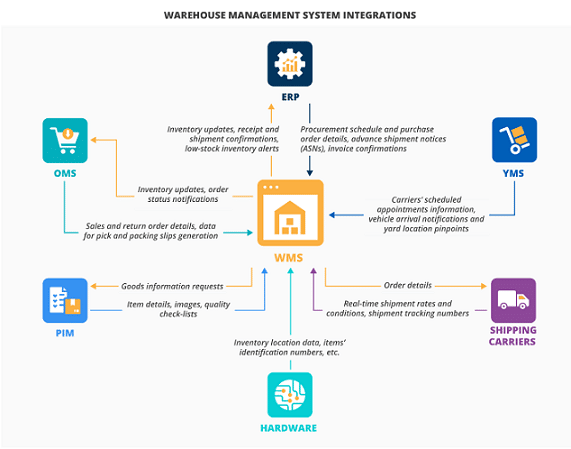

As we’ve explained, a standalone tool can be paired with other related systems, such as an ERP (Enterprise Resource Planning), an SCM (Supply Chain Management), or a TMS (Transportation Management System) to handle inbound and outbound logistics like palletization of goods, cross-docking, and yard management.

WMS tools are usually cloud-based these days, although some larger enterprises may use customized on-premises systems to meet their specific requirements. Cloud-based solutions mean all employees can access the same system and real-time information from any device, anywhere—without the cost or hassle of running on-premises hardware.

Where do warehouse management tools fit in the supply chain?

Warehouse management is a vital link in the supply chain. If your warehouse processes are slow or full of errors, there will be knock-on effects causing disruption throughout the chain, and it doesn’t take much for the whole thing to fall apart.

For instance, if goods are put away in a haphazard manner, there will be a delay in locating the right items for picking and packing, which means that parcels are not ready for collection by the carrier, and you can’t meet the promised delivery slot. Plus, you’ll run into big problems if products are damaged through incorrect storage, or miscounted in a cycle count.

Source: mmh.com

In the competitive world of omnichannel retail, customers expect a wide range of options for purchasing, shipping, and returns—and they expect you to fulfill those expectations as well as their orders. Retail businesses have to respond quickly to demand, by using warehouse management software with advanced fulfillment capabilities.

An effective WMS tool means you can ensure that all your warehousing processes run smoothly, from storing goods properly to tracking shipments and liaising with distributors.

Benefits of using modern warehouse management tools

There are a ton of benefits to implementing modern warehouse management tools. A good WMS, whether it’s standalone or integrated, will help you increase efficiency and accuracy, as well as reducing labor costs and improving customer service.

Faster processes

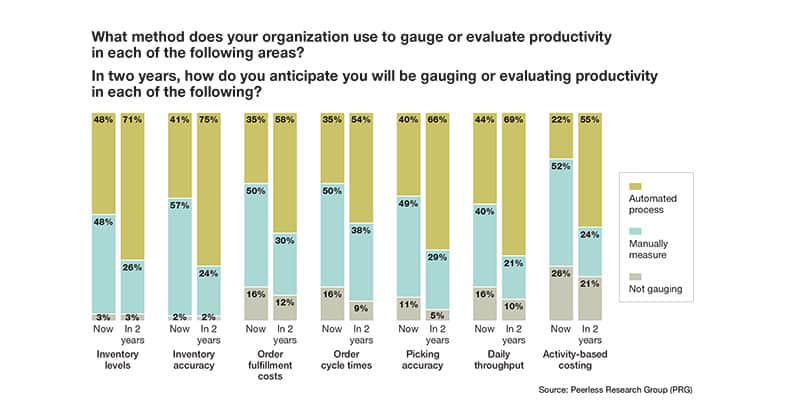

WMS tools often feature a high degree of automation, so you no longer have to rely entirely on manual labor for data entry or processing orders. It’s not surprising that automated tools are growing in popularity—by 2026, the global warehouse automation market is estimated to surpass $30 billion US dollars.

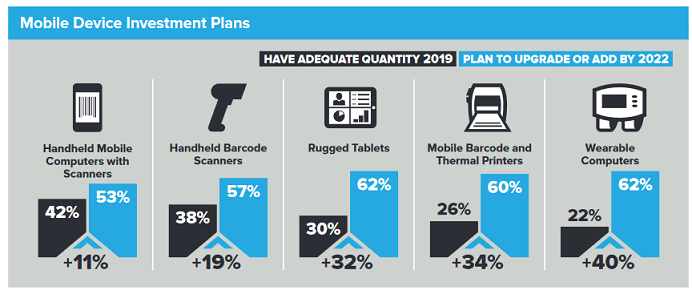

Automation speeds up your workflows and significantly reduces the potential for human error, allowing you to spend more time on complex tasks and optimizing the customer experience. For example, barcode or RFID (radio frequency identification) scanners make it super-easy to log received items into the system and locate them quickly in the warehouse.

With an integrated system like Brightpearl, your warehouse inventory is updated whenever anything changes, and you can auto-generate invoices and shipping labels.

Lower upfront costs

We’ve already mentioned that cloud-based WMS tools are usually more cost-effective than their on-premises counterparts. That’s partly because there’s no upfront expenditure—you don’t need bulky hardware, a large office to house it in, or an IT team to install and maintain it (which gives you a lower total cost of ownership as well).

Most WMS solutions are sold as SaaS (Software as a Service) via a monthly subscription. The software is owned by the vendor, while all the maintenance and upgrades are included in the predictable operating cost. These systems are typically fast to deploy and learn, so employees can get straight down to work.

Source: inoxoft.com

Scalable

The best WMS tools are able to grow with your business, as they’re designed to cope with high order volumes. The cloud gives you increased agility—you can easily add extra users and features to your subscription without having to install new hardware. Since updates are installed automatically, you’re always running the latest version of the system with improved features.

Also, because automation helps you minimize labor costs, small businesses can decide to expand their product lines and customer base without worrying about the high cost of taking on extra staff.

Flexible

Warehouse Management Systems can often be reconfigured to suit changing business requirements or market conditions, with the flexibility to add or remove tools or users. For example, maybe you want to ramp up your operations as you approach the busy holiday season, but scale back again in quieter periods.

All-in-one solutions like Brightpearl also allow you to be flexible with fulfillment, such as choosing dropshipping or partial fulfillment for certain orders, or selecting different shipping carriers based on purchase channel or warehouse location.

Seamless integration

Another important benefit is that you have plenty of opportunities for integration—not just by implementing warehouse management as part of an integrated system, but also through connections with third-party tools. For example, with Brightpearl you can choose to use the built-in retail accounting system, or an integration with Xero or QuickBooks.

The ability to access a wide range of tools in one place is also a bonus for productivity, as there’s no time wasted in toggling between them. It’s also cheaper than buying a bunch of extra tools. And in an integrated Warehouse Management System, data is synced between modules and apps in real-time so that everyone has the latest information.

Source: zebra.com

Improved customer experience

When you get warehouse management right, it’s far easier to keep customers happy with fast fulfillment, fewer errors and delays, and regular updates on the status of their orders. You can provide omnichannel sales, simple returns, and a choice of shipping options.

It’s also possible to offer a wider product range if you know that it’s easy to manage suppliers, track inventory and orders, and be flexible with shipping carriers. With a built-in or integrated CRM, you can use your data to optimize and personalize the customer experience.

What to consider when choosing your warehouse management tool

Some WMS tools are designed for certain types of businesses, so it’s best to carry out your own research and find the solution that best suits your needs. You should also check that the system is easy to set up and learn, and that the vendor offers robust tech support and training.

Here’s some other aspects to consider:

Warehouse design

The design and layout of your warehouse should be a factor in choosing your WMS. An e-commerce vendor will have a different setup than a brick-and-mortar retailer, so their WMS might require different functions. You may also need to configure your WMS for the type of goods you sell. For example, to cover specialized handling of perishable goods.

A WMS helps you to maximize storage space and ensure that the warehouse is designed for optimized inventory allocation. You can also customize your workflows for picking and packing, taking fluctuations in demand into account.

Warehouse size

Larger warehouses require more complex warehouse management, so you’ll need a WMS with full functionality. Basically, the bigger the warehouse, the more advanced the tool needs to be. It’s vital that the system gives you full visibility, especially if you have a wide variety of product lines—and if you’re managing a network of warehouses.

You might choose a WMS tool that’s already designed for the size of your organization, or a product that can scale with you as you expand your warehouse operations (like Brightpearl).

Source: zebra.com

Inventory tracking

It’s extremely important to know the precise location of all your inventory items at any given moment. Are they in transit, in storage, being processed, or on their way to the customer? Ideally, your system needs to update automatically to reflect items being ordered from suppliers, received at the warehouse, transferred between locations, picked, packed, shipped, and potentially returned.

You also need to be aware of what’s being sold on each channel, including in physical stores, so that you can arrange replenishment and ensure stock availability (without falling into the trap of excess stock). It makes sense to use dedicated inventory management software, which may not be part of a standalone WMS.

Receiving and dispatching

A WMS will help you put a system in place for receiving goods, putting them away, and dispatching them. The process should involve using barcode scanners to log SKUs and serial numbers as items arrive and leave, as well as registering their storage location in the warehouse. This will ensure that goods are stored and handled correctly, and are easy for pickers to locate.

The WMS should be configurable to suit your preferred methods, such as FIFO (first in, first out) or LIFO (last in, first out) systems.

Picking and packing of goods

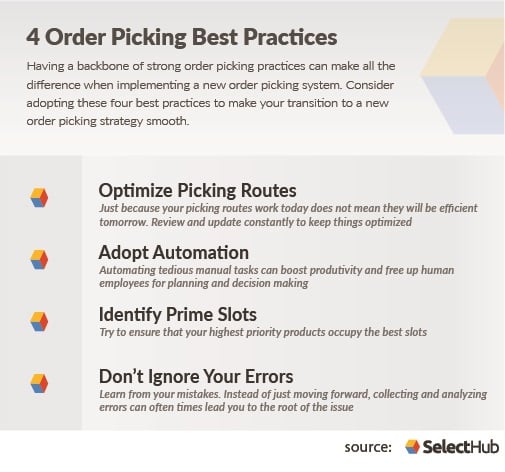

Again, look for a WMS tool that helps you streamline these processes for maximum efficiency. Automation is a key aspect—pickers need to receive the right information quickly when an order comes in, while auto-generated packing slips help to guard against the wrong items being packed and sent out. This is particularly important for multi-item orders and kitting.

Your Warehouse Management System should enable you to choose the most appropriate picking method, whether it’s batch, wave, zone, or cluster picking. It’s helpful if you can arrange storage so that your best-selling items are nearest to the packing station—which means you also need an analytics tool to determine what those items are.

Source: selecthub.com

Shipments

Successful shipping depends on successful warehouse management—you need to get the right goods packed and ready for loading onto a carrier’s vehicle, with all parcels bearing the correct labels and the drivers given the correct delivery information with optimized routes.

It’s definitely easier if you use an integrated WMS with modules for fulfillment and shipping, or at least connect your WMS to a shipping app. That way, you’ll be able to manage multiple carriers, auto-print shipping labels and customs forms, and track shipments to the customer’s door.

Management of labor

A WMS with full analytics capability is essential for efficient labor management. You can use historic data to figure out how many workers are needed at certain times, such as peak seasons and holiday periods. You can also evaluate how automation is boosting production and reducing costs.

Warehouse managers can use KPIs to monitor staff performance, and offer extra training to anyone who’s falling behind. Plus, with full inventory visibility, you can keep an eye out for damage caused by incorrect handling, or any goods being stolen.

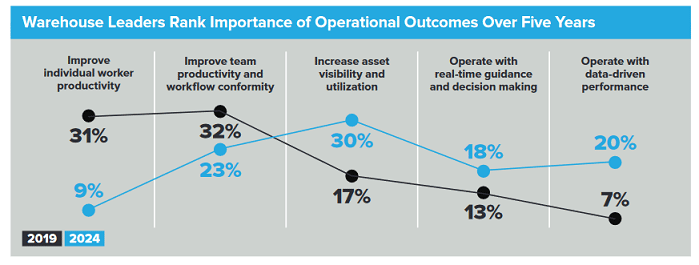

In a recent survey, 89% of organizations say they will be using modernized Warehouse Management System functionality for labor planning and management by 2024.

Yard management

Yard management involves having real-time information to help you monitor the movement of trucks or trailers in the yard of your warehouse. That way, you can easily direct inbound and outbound vehicles (as well as personnel, shipments, and pallets) and assist truck drivers to find the right loading docks.

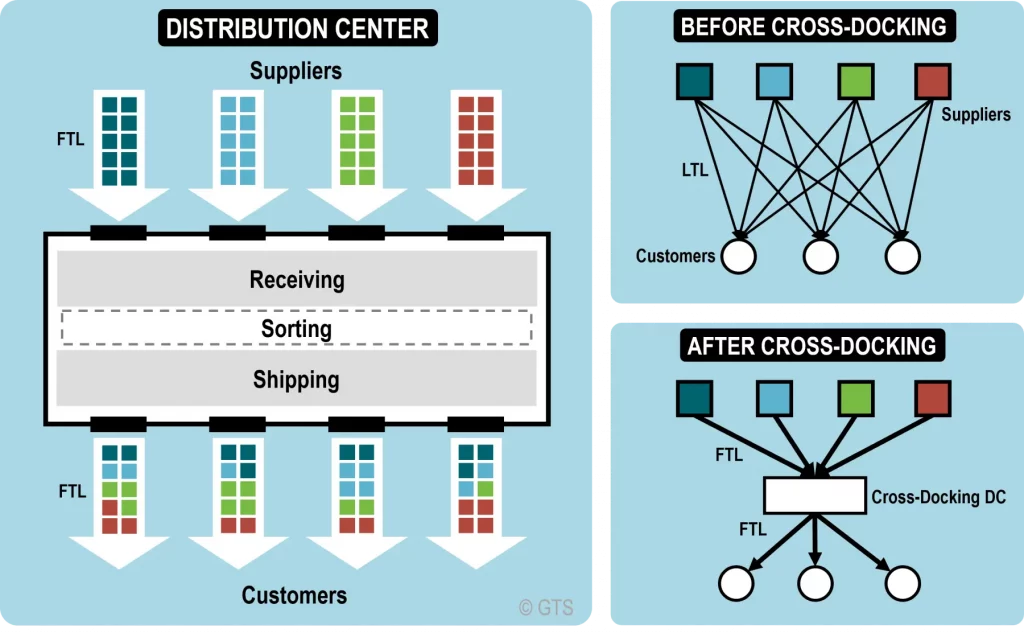

Yard management enables cross-docking, where goods from a supplier or manufacturer arrive at your facility but are screened, sorted, and loaded onto trucks for delivery, with no storage time in between. It’s often used in conjunction with warehouse management and transportation management systems, in tools like Infor SCM.

Source: transportgeography.org

Cost

Obviously, your budget is a big consideration when choosing a WMS tool. The cost of a standalone or an integrated tool will depend on its complexity and functionality. The most important thing is that you get value for money by ensuring the system helps you achieve your goals.

The good news is that whatever price you pay for your WMS, the increased efficiency will save you money over time. You’ll have fewer errors or stock losses, and cloud-based tools eliminate installation and maintenance costs. With a well-run warehouse and a strong relationship with suppliers and carriers, you could switch to a just-in-time inventory model to save on storage costs.

Customer needs

As well as increasing your company’s profits, one of the aims of warehouse management should be to meet (or even exceed) customers’ needs and expectations. When you’re selecting a WMS tool, look at the functionality from the customer’s point of view.

Look at the feedback—are you getting lots of complaints about delivery delays, incorrect items being sent out, or out-of-stock items listed for sale on your website? Your WMS tool should give you the means to find out what customers want and how you can improve. Information from your CRM is also useful here.

Why choose Brightpearl’s retail operating system rather than a standalone warehouse management tool?

Brightpearl falls into the category of integrated WMS tools, in that its warehouse management capabilities sit alongside inventory management, order management, fulfillment, and shipping (to name a few). However, these don’t take the form of separate modules—they all work together seamlessly, making Brightpearl far more than the sum of its parts.

Even though it’s packed with advanced features that flex to fit your business needs, Brightpearl also gives you access to a ton of plug and play integrations, enabling you to bring all your tools into one platform for optimum efficiency.

Why should you trust Brightpearl for your warehouse management needs?

Here’s why it’s better for your business to use Brightpearl rather than a standalone WMS:

It’s built for retail

Brightpearl is a retail operating system, which means it’s been designed by experts specifically for e-commerce, retail, and wholesale merchants. It gives you all the features you need to operate your business smoothly, without becoming overwhelmed by tools you’ll never use. Built to cope with high order volumes, it enables you to offer omnichannel retail and multi-location fulfillment, syncing data between your online and offline stores.

Customer support is provided by retail experts, too. As well as quick-access to 24/7 support, you get guided implementation (with a success rate of 97%), plus ongoing business consulting—all at no extra cost.

It gives you full supply chain visibility

Brightpearl understands how warehouse management fits into the wider supply chain, and why it’s so important that all the different stages work together. That’s why it gives you complete visibility of all your operations, not just for warehouse management. You can easily monitor stock levels and set reorder points to ensure inventory accuracy, with the built-in POS showing you real-time availability.

It’s also easy to track orders throughout their journey, and to manage your suppliers, shipping carriers, and 3PLs. While standalone solutions typically offer limited reporting functionality, Brightpearl provides advanced analytics and reports. The data is displayed on intuitive dashboards, enabling you to make accurate forecasts. Plus, you can keep a close eye on your financials with integrated retail accounting and purchasing.

It improves efficiency and productivity

Because all your tools are in one platform, there’s no need to use a separate SCM, TMS, or OMS like you would with a standalone WMS. That means your workforce is more productive, as they don’t have to constantly switch between systems. Brightpearl is super-easy to deploy and learn (with full support provided).

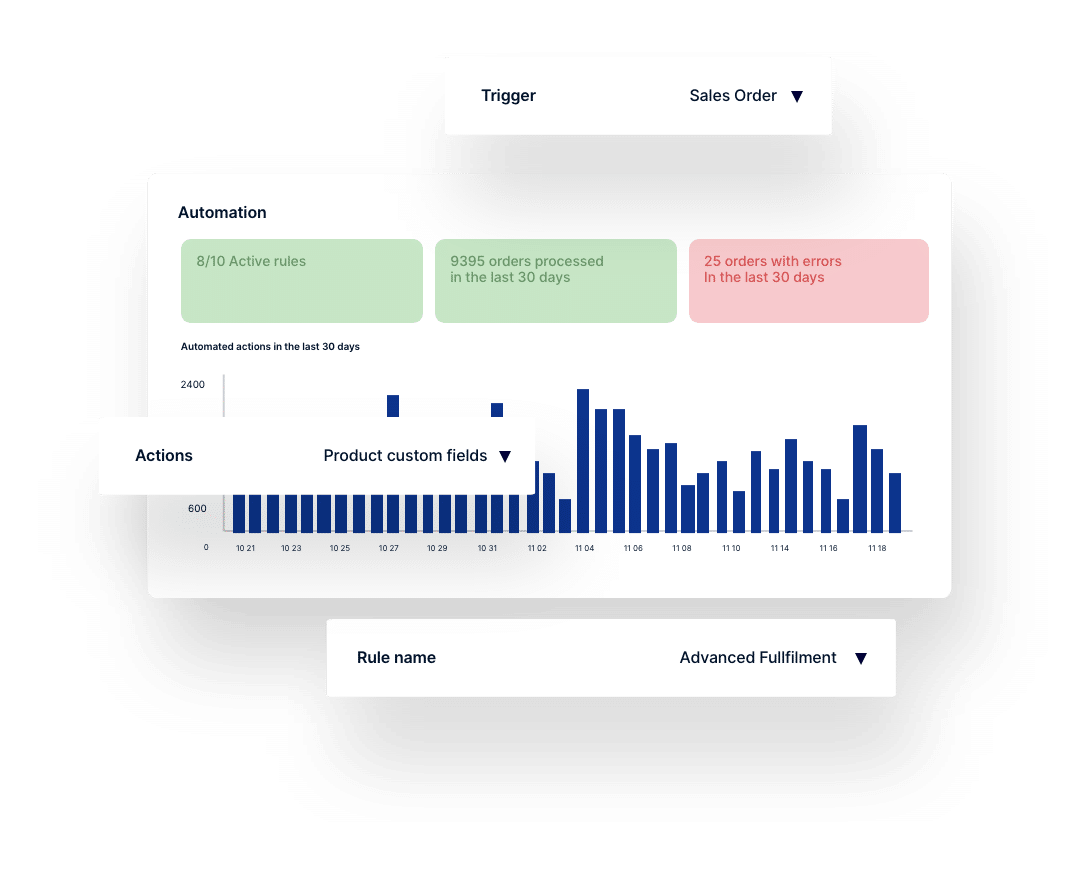

Brightpearl’s Automation Engine also boosts efficiency, and takes the effort out of processing complex orders—including those from multiple locations, and anything involving dropshipping, partial fulfillment, or FBA. All of which leads to a better customer experience.

Less advanced systems can hamper your efficiency because they’re unable to handle an increase in order volumes. That’s not the case with Brightpearl, which has connections to e-commerce platforms and other systems designed to exchange data quickly.

It reduces your costs

Brightpearl is a cloud-based platform, which means it’s far simpler to set up and less expensive to manage than a traditional on-premises WMS (which can take months to implement). You don’t have to worry about paying for or installing updates, which arrive without causing any disruption to your business.

Automation saves you money by improving productivity, and Brightpearl enables companies to cut their labor costs by 50%. It also helps you to reduce human error by 65%—meaning you won’t lose money on things like damaged goods, excess stock, rescheduled deliveries, or compensating customers for delays.

It’s highly scalable

Brightpearl isn’t a system with a one-size-fits-all approach—it’s flexible enough to suit all types of organization. It’s been designed with the intention of helping large, small, and medium-sized businesses to Grow Fearlessly, which means you can open extra warehouses and sell on new channels without worrying about whether your tools can cope with the growth.

Standalone solutions are not particularly scalable, as you’ll have to spend money on extra tools and try to bolt them on to the existing system. But with Brightpearl, you can quickly and easily add new sales channels and cutting-edge tools whenever you need them, and add extra users to your subscription at busy times.

Integrations help you build a customized tech stack, while automatic updates mean you’re always using the latest version of the system.

Brightpearl’s best warehouse management features

While Brightpearl has you covered for every aspect of your retail operations, you’re reading this to learn more about warehouse management. Brightpearl has an array of tools designed for this purpose, including a separate login and interface for your warehouse management team that focuses on the information, workflows, and functionality they require.

Let’s look in more detail at Brightpearl’s WMS capabilities:

Automate for efficiency

With barcode scanning technology, your employees can quickly and efficiently scan products when receiving goods, creating and processing returns and transfers, or counting inventory. There are even audio alerts to help workers avoid picking incorrect items.

Meanwhile, Brightpearl lets you create automated pick, pack, and ship workflows that significantly reduce mispicks and mispacks to help you keep customers happy. It also automates fulfillment on certain predefined orders, so you can guarantee faster delivery times. (In fact, the Automation Engine can reduce shipping time by 92%.)

Set your own rules

Brightpearl enables you to automate warehouse workflows based on your specific needs. You can also customize your goods out workflows, and choose between the default FIFO (First-In, First-Out) model for inventory allocation and alternative options based on your preferences. Use your preferred criteria to batch shipments together, and create the most efficient pick routes through the warehouse to drive down handling time and get orders out faster.

Be flexible with counting

Flexible cycle counts help you to keep a close eye on your inventory and check for damage, theft, or spoilage, without cutting into your business’ productivity. You can perform full or partial inventory counts at the click of a button, and tailor them based on anything from location and throughput to value and product attributes. Brightpearl also automatically enables partial counts by zone, and updates your sales channels accordingly.

Reconcile deliveries and returns

When new inventory arrives at your warehouse, you can reconcile it against specific purchase orders, transfers, or sales credits in Brightpearl so that your warehouse team and other staff are always on the same page.

Plus, the process of managing returns and refunds is made simple for both customers and employees. When customers send return items back to you, Brightpearl automatically initiates the sales credit process as soon as the items are received in the warehouse.

Plan ahead

Brightpearl’s WMS features work in conjunction with the Demand Planner, which gives you insights into product performance as well as data-driven replenishment reports. Coupled with full visibility of your inventory at each stage of its journey, it enables you to create highly accurate demand forecasts. You can avoid the problems of stockouts or carrying excess stock, and find out which product lines are worth continuing.

Analytics and reporting also help you to figure out ways to improve your warehouse management practices, and put processes in place to prevent any issues from happening in the future.

How to start working with Brightpearl

As mentioned already, it’s very simple to deploy Brightpearl and get to grips with its intuitive features. Once you get in touch with our team, they’ll scope out your project and present you with a Technical Solution Proposal detailing exactly how the system will be implemented to meet your unique workflows and requirements.

You’ll then receive a fixed cost quote with a full breakdown of pricing before you sign your contract. (Brightpearl’s pricing couldn’t be simpler— it’s based on your rate of growth.). Brightpearl will migrate, review, and structure all your data, and make sure the platform is configured for your needs and seamlessly connected to all your channels and systems.

Every Brightpearl customer is matched with their very own Customer Success Team, who will regularly check in on your account to ensure everything is running as it should be. They’ll also put together a customized Success Plan and work with you to help you meet your targets. The consultants will continue to finetune the workflows and solutions based on your feedback.

You receive robust training as part of the onboarding process, but Brightpearl also offers a product training platform, or learning management system (LMS), designed to help users learn how to get the best out of the system.

Plus, there are in-depth help guides for how to do the basics, such as setting up customer and product records, buying and receiving stock, selling and shipping items, generating invoices, and taking payments.

Every time you log in to your account, the Home Dashboard provides an overview of your company activity in one place, including sales, accounts, helpdesk, and products (or you can set any other screen as your homepage for convenience). Notifications refresh every five minutes.

In the Settings area, you can control and create all the details you need in order to tailor Brightpearl to your own processes. There are handy short-cuts to viewing customer or supplier account information, while the Favorites feature allows you to save quick links to anywhere in Brightpearl.

Final Thoughts

It’s clear that advanced warehouse management software is not only necessary but crucial for running a successful retail business and ensuring you don’t become the weak link in the supply chain. Using technology to maintain visibility and automate processes will also help you reduce costs, meet growing demand, and keep customers satisfied.

However, 61% of operational decision makers agree that IT or technology utilization is their biggest operational challenge now and within the next five years. Meanwhile, 77% of respondents agree that they need to modernize their warehouse operations but admit they are slow to implement new devices and technology.

This needn’t be the case for your business: Brightpearl makes it easy to implement and improve warehouse management practices. As an integrated system, its advanced WMS capabilities work seamlessly with features for inventory control, order management, fulfillment, shipping, and more. There’s no limit on the number of users, and the platform is designed to help your business grow.

To learn more about why Brightpearl is the best warehouse management software option, visit the website and chat to the friendly team about your personalized quote.